Do the Math: How Handheld Laser Welding Machines Dramatically Reduce Your Cost Per Part

Are U.S. Welder Wages Too High?Do the Math: How Handheld Laser Welding Machines Dramatically Reduce Your Cost Per Part

In workshops across Texas, Ohio, and California, job postings for skilled welders stay open for months—while hourly wage bills keep hitting new highs week after week. This is no longer just a “cost” issue. It has become a crisis of capacity, reliability, and production certainty.

Yet within every crisis lies opportunity. A productivity shift driven by handheld laser welding technology is enabling forward-thinking U.S. manufacturers to significantly reduce per-part welding costs—and regain control over their operations.

This article is more than a cost analysis of handheld laser welding machines. It is a practical, factory-level transformation guide designed specifically for U.S. manufacturers.

Chapter 1 – The True Cost Breakdown: What “Hidden Taxes” Are You Paying for Every Weld?

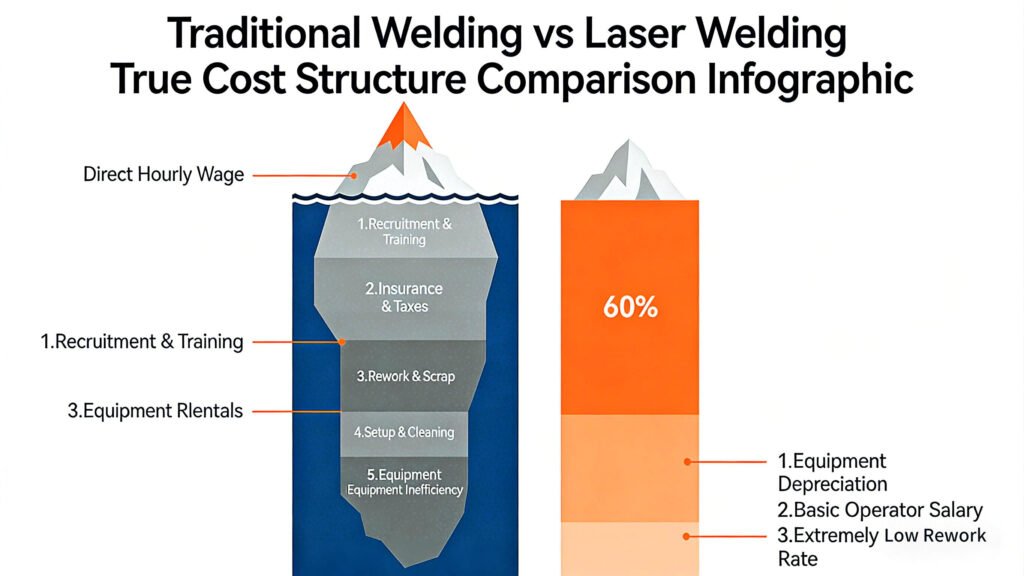

1.1 Direct Labor: Hourly Wages Are Only the Tip of the Iceberg

According to the latest data from the U.S. Bureau of Labor Statistics, the average base hourly wage for welders in the Great Lakes region—the traditional industrial heartland of America—has reached $28 per hour.

But that figure tells only part of the story.

In real-world manufacturing cost accounting, the Fully Burdened Labor Cost must also include:

-

Federal and state payroll taxes

-

Health insurance

-

Retirement contributions

-

Workers’ compensation

-

Supervisory and administrative overhead

In most U.S. shops, this results in a cost multiplier of 1.4 to 1.6×, pushing the true hourly cost of a skilled welder to $39–$45 per hour, or even higher.

This rigid and continuously rising expense has become one of the largest—and least predictable—financial burdens for metal fabrication businesses.

1.2 The Efficiency Tax: The Capacity Black Hole No One Talks About

The real cost of welding extends far beyond arc-on time.

Fixture setup, surface cleaning, post-weld grinding or straightening, machine setup, and parameter tuning often consume 30%–50% of total labor time. These non-welding activities quietly drain capacity—yet are rarely tracked or optimized.

1.3 The Risk Tax: Quality Variability and Talent Dependency

Manual welding quality depends heavily on the welder’s skill level and daily condition, leading to unpredictable rework and scrap costs.

Even more critically, the U.S. manufacturing sector is facing a severe skills gap. A single experienced welder’s absence—or resignation—can delay deliveries and jeopardize customer relationships. This dependency risk represents a substantial but often invisible cost.

Chapter 2 – Why Handheld Laser Welding Is Not a “Faster Torch,” but a Fundamentally Different Tool

2.1 From Heat Conduction to Keyhole Welding: A Physical Leap in Efficiency

Traditional arc welding relies on heat conduction—essentially “melting” metal with sustained thermal input.

Handheld laser welding, by contrast, concentrates extremely high energy density into a focused beam, creating a keyhole that produces deep, narrow welds. The result is a dramatically smaller heat-affected zone and minimal distortion—reducing downstream finishing at a fundamental, physical level.

2.2 How Technical Advantages Translate Into Shop-Floor Gains

-

Speed: With concentrated energy and high deposition efficiency, welding travel speeds can reach 2–5× that of MIG welding.

-

Appearance & Quality: Virtually no spatter; post-weld finishing time can be reduced by over 80%.

-

Tolerance & Flexibility: Excellent gap-bridging capability and lower fit-up requirements. The handheld design allows operators to weld large, complex, or fixed-position parts with the same freedom as a traditional torch—something automation simply cannot match.

These advantages ultimately show up where it matters most: your financial statements.

Chapter 3 – Where the Savings Come From: A Real-World Cost Simulation

3.1 Building Your Cost Model

A simplified formula reveals the structure of welding costs:

**Cost per part = (Preparation time + Welding time) × Labor rate

-

Consumables + Rework risk**

A handheld laser welding machine positively impacts every variable in this equation.

3.2 Scenario Simulation: 1,000 Stainless Steel Brackets

The following example uses idealized assumptions for demonstration purposes. Actual savings vary by application.

| Cost Item | Traditional MIG Welding | Handheld Laser Welding | Impact Explanation |

|---|---|---|---|

| Welding time per part | 2.5 min | 0.8 min | High energy density enables much faster welding |

| Prep & cleanup time | 1.5 min | 0.2 min | Minimal spatter and distortion |

| Fully burdened labor rate | $45/hr | $30/hr | Easier training, lower skill dependency |

| Direct labor cost per part | $3.00 | $0.50 | $2.50 saved per part (83%) |

| Shielding gas | $0.15 | $0.05 | Lower gas consumption |

| Filler wire & consumables | $0.25 | $0.10 | Higher deposition efficiency |

| Rework & scrap risk | $0.50 (est.) | $0.10 (est.) | Highly consistent process |

| Total cost per part | $4.00 | $0.90 | $3.10 reduction per part |

| Annual cost (10,000 pcs) | $40,000 | $9,000 | $31,000 |

Chapter 4 – Choosing the Right Handheld Laser Welding Machine for U.S. Shops

4.1 Key Parameters: Power and Practical Flexibility

For common U.S. fabrication, repair, and light production tasks (material thickness 0.5–6 mm), a 1000W–1500W handheld laser welder offers the optimal balance.

Equally important are stable output, precise pulse control, and adaptability for challenging materials such as aluminum and copper.

4.2 Local U.S. Support: Your Operational Safety Net

When purchasing a handheld laser welding machine in the U.S., local support capability is critical.

-

Parts & Logistics: JOYLASER operates a U.S. shipping and spare parts center in Los Angeles, California, ensuring fast domestic delivery of machines and consumables.

-

Global Technical Support: Backed by senior application engineers in China and India, we provide 24/7 remote technical support.

-

Compliance & Safety: Our handheld laser welding machines meet CE standards, comply with NRTL testing requirements, and conform to FDA 21 CFR Part 1040.10, as well as RoHS and FCC regulations.

-

Sample Testing & Training: We offer flexible sample testing and structured English training materials to ensure operators achieve safe and fast proficiency.

Chapter 5 – From the Shop Floor: A U.S. Manufacturer’s Transformation Story

Customer: “Great Lakes Metalworks” (name changed), a family-owned Tier-2 automotive supplier in Indiana.

Challenges:

-

Severe welder shortages

-

Fully burdened labor costs exceeding $48/hour

-

Inconsistent weld quality

Solution:

After sample testing and a clear ROI analysis with JOYLASER, the customer invested in a 1500W handheld laser welding machine, shipped directly from our Los Angeles distribution center. The machine arrived at their Indiana facility within three business days.

Results after 6 months:

-

Labor hours reduced by 62%

-

Cost per part reduced from $8.50 to $3.20

-

Annualized savings exceeding $42,000

-

Weld acceptance rate reached 99.98%, with zero customer complaints

-

Skilled welders reassigned to higher-value projects

Customer Testimonial:

“This JOYLASER handheld laser welder completely changed how we respond to labor shortages and cost pressure. From transparent ROI calculations to fast U.S. support and simple training, the entire process was smoother than we expected.”

— Operations Director, Great Lakes Metalworks

Conclusion – Ready to Calculate Your Own Savings?

You’ve seen the numbers and heard from peers in your industry. Now it’s time to evaluate what a handheld laser welding machine can do for your operation.

Whether through free sample testing or a customized Efficiency & Cost Reduction Assessment, the JOYLASER team is ready to support your decision with clear, data-driven insights.

👇Contact our U.S. market team today and start your efficiency evaluation.

111-1024x458.png)