Fiber Laser vs. UV Laser Marking Machines: The Definitive Selection Guide for U.S. Manufacturing

Introduction: The Strategic Imperative of Permanent Part Marking in U.S. Manufacturing

Across the competitive landscape of American manufacturing—from medical device labs in Minnesota to aerospace facilities in Washington—a fundamental requirement unites successful operations: permanent, precise, and reliable part identification. Whether for traceability, regulatory compliance, or brand protection, marking is no longer optional; it’s a strategic necessity that impacts your bottom line, supply chain integrity, and market access.

When investing in a laser marking system, the critical question isn’t merely “Should we buy one?” but rather, “Which laser technology is perfectly matched to our specific materials, production processes, and compliance requirements?”

For most American shops, the decision narrows to two proven industrial technologies: Fiber Laser Marking Machines and Ultraviolet (UV) Laser Marking Machines. Choosing incorrectly risks unreadable marks, product damage, audit failures, and stranded capital. This guide cuts through the confusion, providing a clear, application-driven comparison to ensure your decision drives efficiency, not regret.

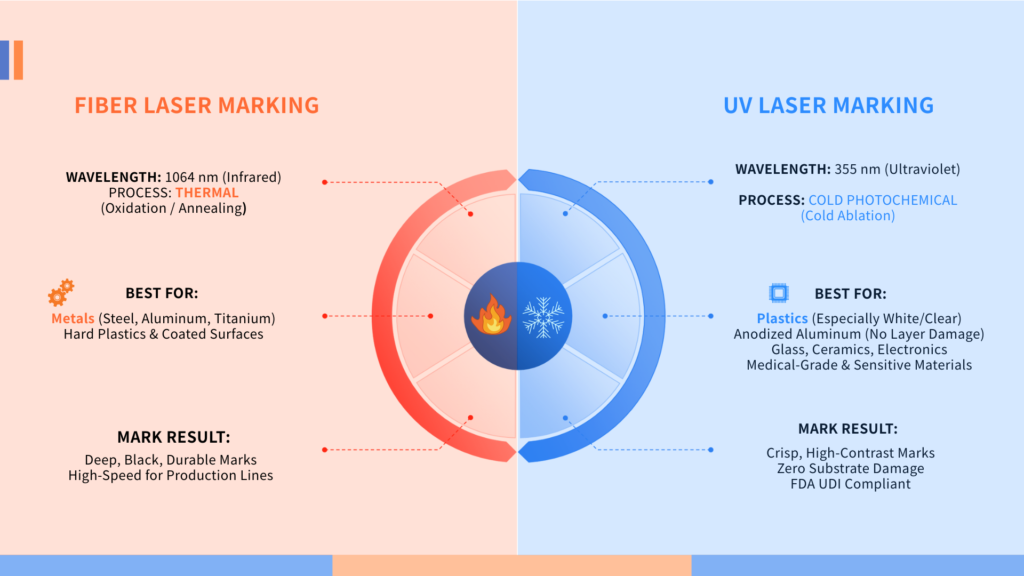

Chapter 1: Core Technology Showdown – It All Comes Down to Wavelength

1.1 Fiber Laser Marking: The Workhorse of Thermal Processing

Fiber lasers are the industry standard for marking most metals and engineered plastics. Operating at a 1064 nm wavelength (infrared spectrum), they deliver high peak power that interacts with materials primarily through thermal effects. Processes like annealing, engraving, or foaming create durable, often deep-contrast marks. Think of it as the reliable, powerful pen for industrial work.

1.2 UV Laser Marking: The Specialist for Cold, Precision Processing

UV lasers operate at a much shorter 355 nm wavelength. Their “cold marking” process works by breaking molecular bonds with minimal heat input. This makes them ideal for heat-sensitive, highly reflective, or delicate materials where substrate damage is unacceptable. Think of it as the surgical scalpel for surface precision.

Chapter 2: Head-to-Head Comparison – Make a Data-Driven Choice

The best choice depends on your primary materials, mark requirements, and production cadence. Use this matrix as your key decision filter.

| Decision Factor | Fiber Laser Marking Machine | UV (Ultraviolet) Laser Marking Machine |

|---|---|---|

| Best-Suited Materials | Metals (steel, aluminum, titanium), many hard plastics, coated metals. | Plastics (especially white/clear), anodized aluminum (without damaging the layer), glass, ceramics, silicon, highly reflective metals (gold, copper). |

| Marking Principle | Thermal effect (annealing, engraving, foaming). | Photochemical reaction (“cold” ablation, color change). |

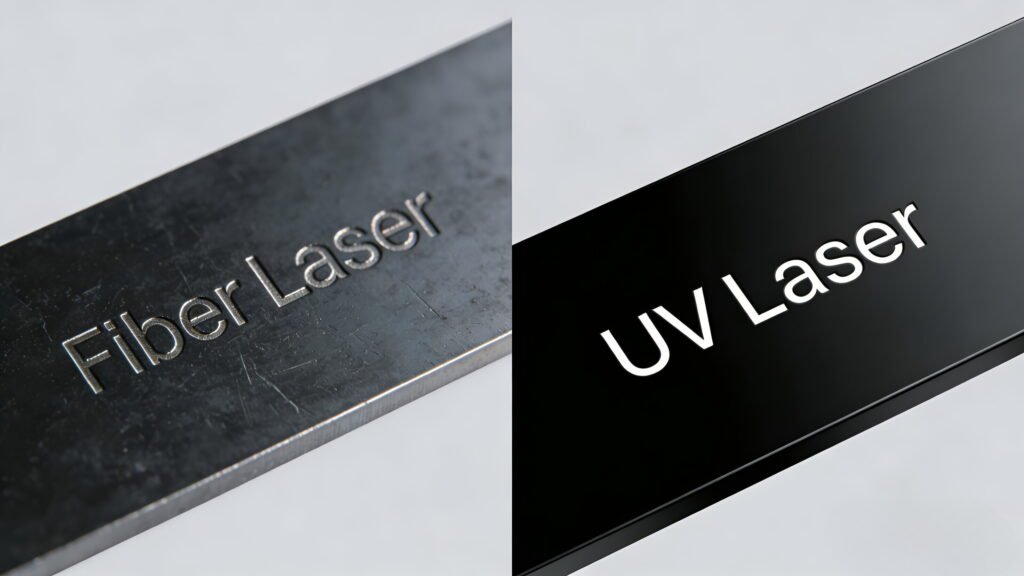

| Mark Appearance | Dark/black or engraved marks on metals; capable of deep engraving. | High-contrast, often bright or colored marks on plastics; exceptionally fine, crisp edges. |

| Heat-Affected Zone (HAZ) | Present (can affect heat-treated surfaces). | Negligible. No thermal damage to surrounding material. |

| Typical Marking Speed | Very fast for most metals. | Slower for comparable depth, but optimal within its specialty range. |

| Key U.S. Applications | Durable tool serial numbers, automotive VIN codes, industrial part IDs. | Medical device UDI codes (FDA compliance), electronics micro-marking, cosmetic packaging, precision branding on anodized aluminum. |

| Operational Cost Profile | Lower consumable cost, generally robust and durable. | Higher initial laser source cost; may require a more controlled environment. |

2.1 When to Confidently Choose a Fiber Laser

Your shop likely needs a Fiber Laser if: Your primary materials are stainless steel, aluminum alloys, or hard plastics; You require deep engraving for abrasion resistance; Your marking volumes are high and speed is critical; Your budget seeks the optimal balance of performance and cost.

2.2 When a UV Laser is the Only Correct Choice

Invest in a UV Laser if: You are marking medical devices or implants requiring FDA-compliant, residue-free marks with zero material alteration. You work in electronics or semiconductors where microscopic, heat-free marking is essential. Your products are consumer-grade anodized aluminum (e.g., water bottles) where marks must be perfectly crisp without burning the colored oxide layer.

Chapter 3: Beyond the Beam – Critical Considerations for U.S. Buyers

3.1 Compliance & Regulations: The Non-Negotiable Line

For U.S. manufacturers in regulated industries, the laser marker is a compliance tool. UV lasers are often the mandated choice for meeting FDA Unique Device Identification (UDI) marking requirements on certain plastics and implants. Ensure your supplier understands these standards and can provide necessary documentation and process validation support.

Compliance Documentation Support: To facilitate your procurement compliance, we can provide the key laser safety certification information for our equipment. Should your internal EHS (Environmental, Health, and Safety) review or customer audit require more detailed technical documentation, our team will assist in connecting and communicating with the relevant parties to complete the necessary compliance procedures.

3.2 Software & Integration: The Brain of the System

The laser source is only half the system. Powerful, intuitive, U.S.-operator-friendly software is crucial for easy graphic design, serialization, database connectivity, and integration with existing MES or ERP systems. Ask: Can it import CAD files seamlessly? Does it support variable data and barcodes?

3.3 Total Cost of Ownership & ROI: The Real Financial Picture

This connects technology to business viability.

Initial Investment Analysis:

Fiber Laser Markers: Typically offer a more competitive entry point with a strong price-to-performance ratio for standard industrial configurations.

UV Laser Markers: Command a higher initial investment due to the cost of DPSS UV laser sources and precision ultraviolet optics. The premium varies by configuration and power.

Lifetime Cost Perspective & ROI Logic:

| Cost Component | Fiber Laser System (Typical Profile) | UV Laser System (Typical Profile) | Procurement Insight |

|---|---|---|---|

| Laser Source Lifespan | Extremely long (tens of thousands of hours) | Defined lifespan (e.g., 10,000-20,000 hours) – a key consumable. | Clarify the rated lifespan (MTBF) and replacement cost with your supplier. |

| System Energy Use | High photoelectric efficiency, lower operating cost. | Requires precise temperature control, generally higher system energy draw. | Long-term utility cost difference is a factor. |

| Quality & Risk Value | Reduces rework, improves traceability. | Eliminates risk of entire batch scrap, recalls, or regulatory penalties due to non-conforming marks. | In medical/electronics, the UV system’s risk-mitigation value can far outweigh the price differential. |

Core ROI Logic: While UV systems often have a higher upfront cost, their Total Cost of Ownership (TCO) must be evaluated in context. For regulated industries, the risk-mitigation value—avoiding batch failures and audits—can justify the premium, leading to a strong risk-adjusted return. For high-volume metal marking, the fiber laser’s lower upfront and operational costs typically deliver the most direct and rapid financial payback.

Chapter 4: Real-World Results – How U.S. Manufacturers Deploy the Right Technology

Case A: From Scrap to Compliance (UV Laser)

A Colorado-based medical device contract manufacturer struggled with low-contrast, inconsistent inkjet marks on polycarbonate housings, leading to line stoppages and audit risk. Switching to a JOYLASER UV Laser Marking System delivered permanent, high-contrast UDI codes with 100% readability, eliminating scrap and ensuring ongoing FDA compliance.

Case B: Shop Floor Efficiency Multiplied (Fiber Laser)

An Indiana automotive supplier needed to mark thousands of steel transmission parts daily. Their outdated dot peen marker was a bottleneck. Deploying a JOYLASER Fiber Laser Marker increased marking speed by over 300%, produced clearer, more durable marks, and reduced maintenance downtime to near zero, paying for itself in under 8 months.

Chapter 5: Frequently Asked Questions for U.S. Buyers

Q1: If my shop needs to mark both metal and plastic, do I need two machines?

A: Not necessarily, but prioritization is key. If your core business is metal marking, choose a Fiber Laser Marker; it can handle basic marking on many plastics. If your core business and compliance needs are in plastics/medical devices, a UV Laser Marker is essential. A free material test is the best way to make the most cost-effective decision.

Q2: What are the key regulatory requirements for using a laser marker in the USA?

A: Key requirements include:

Radiation Safety: Compliance with FDA CDRH regulations (21 CFR 1040.10). Industrial markers are classified as Class 1 Laser Products when properly enclosed.

Workplace Safety: Adherence to OSHA guidelines, supported by proper machine guarding, interlocks, and safety documentation.

We provide relevant laser safety information to support your facility’s EHS assessments.

Q3: How does JOYLASER compare to established U.S. laser brands?

A: Our value proposition is “Industrial-Grade Performance with Exceptional Value”:

Industrial Focus: Our systems are engineered for production-floor reliability and integration, not as general-purpose engravers.

Significant Value Advantage: We deliver comparable or superior industrial performance while typically offering substantial cost savings.

Agile Application Support: We provide responsive, deep parameter optimization support for challenging materials.

U.S. Logistics Support: Our West Coast support center and warehouse enable fast spare parts availability to maximize your uptime.

Conclusion: Equip Your Line with Confidence, Not Guesswork

The choice between Fiber and UV laser marking isn’t about which technology is “better”—it’s about which one is perfectly matched to your product, process, and regulatory landscape. A misaligned choice costs you daily in quality, speed, and compliance.

[🔬 Request Your Free Material Test & ROI Evaluation]

Move from theory to proof. We offer a complete decision-support service:

Free Professional Sample Testing: Send us your key materials. We’ll test them on both Fiber and UV platforms.

Detailed Comparison Report: Receive a report with high-resolution result images, speed data, and parameter recommendations.

Preliminary Value Assessment: Discuss potential efficiency gains, cost savings, and risk reduction with our engineers.

Stop guessing. Use definitive test data to justify your capital investment.

Facing manufacturing challenges beyond marking? Explore our other U.S.-market laser solutions:

Disclaimer: The technical principles, performance comparisons, application examples, and cost analyses mentioned in this article are based on general industry knowledge and typical scenarios. They are intended for informational purposes only and do not constitute a guarantee of specific equipment performance or a formal business offer. Actual equipment selection, performance, pricing, and return on investment will vary based on specific materials, process parameters, configuration choices, and market conditions. Please rely on the final test reports, technical proposals, and quotations provided by the official JOYLASER technical team.

👇[Link: Handheld Laser Welder Page] – For flexible repair and light assembly.

👇[Link: Automated Laser Welding Workstation Page] – For high-precision, high-volume welding.

111-1024x458.png)