JOYLASER Laser Welding Machines — Reliable Power for Every Metal Connection

- Home

- »

- Laser Welding Machine

Laser Welding Machine

JOYLASER laser welding machine is designed for efficient and precise metal joining. Using advanced fiber laser technology, it offers strong, clean, and smooth welds on stainless steel, aluminum, carbon steel, and brass. Widely used in industries such as electronics, automotive, hardware, furniture, and kitchenware manufacturing, it provides stable performance and minimal heat distortion. With easy operation and low maintenance, JOYLASER laser welding machines are the perfect choice for factories seeking high-quality, high-speed welding solutions.

Handheld Laser Welding Machine

Platform Fiber Laser Welding Machine

Mold Laser Welding Machine

Materials Our JOYLASER Welding Machines Can Weld

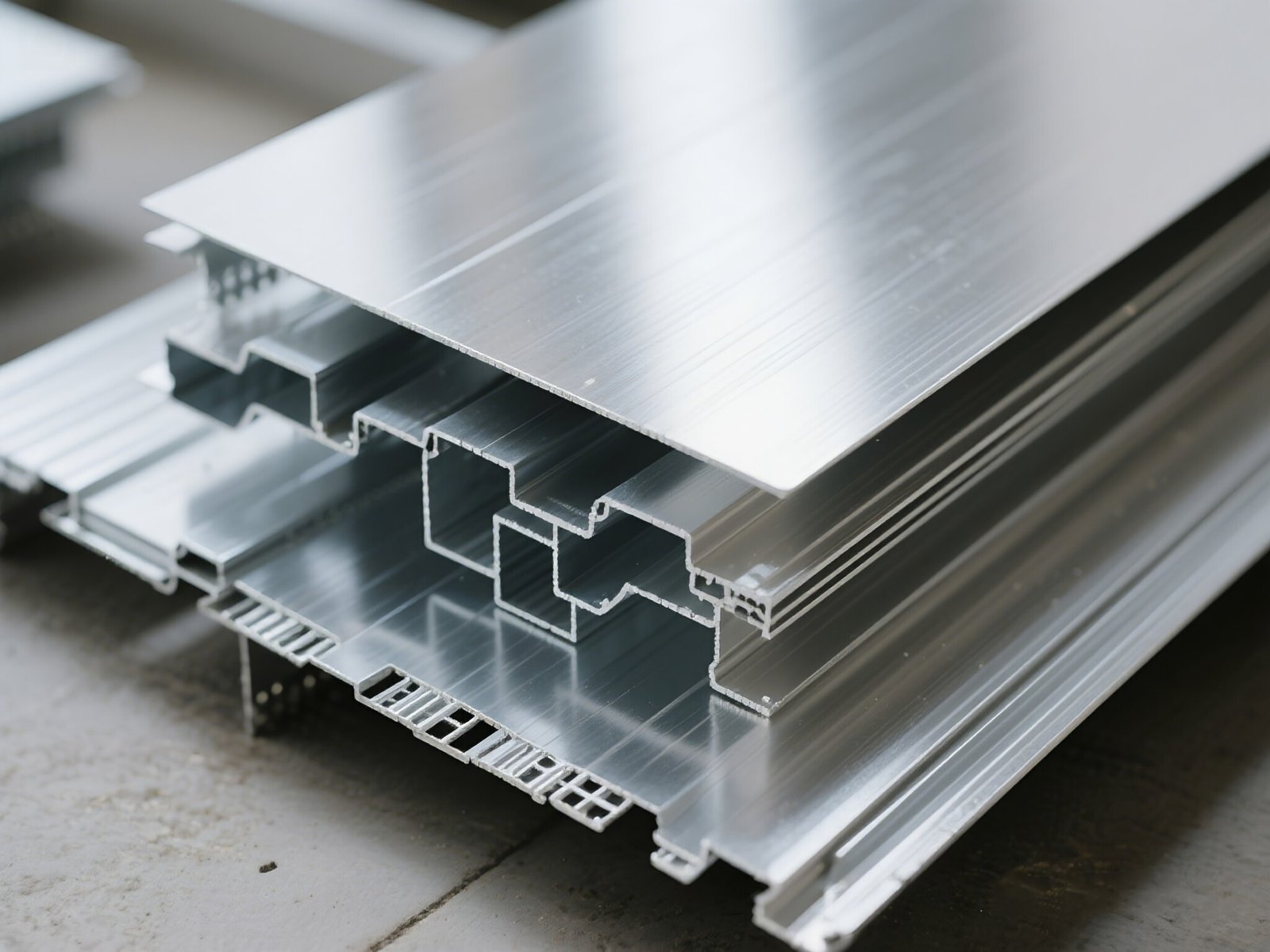

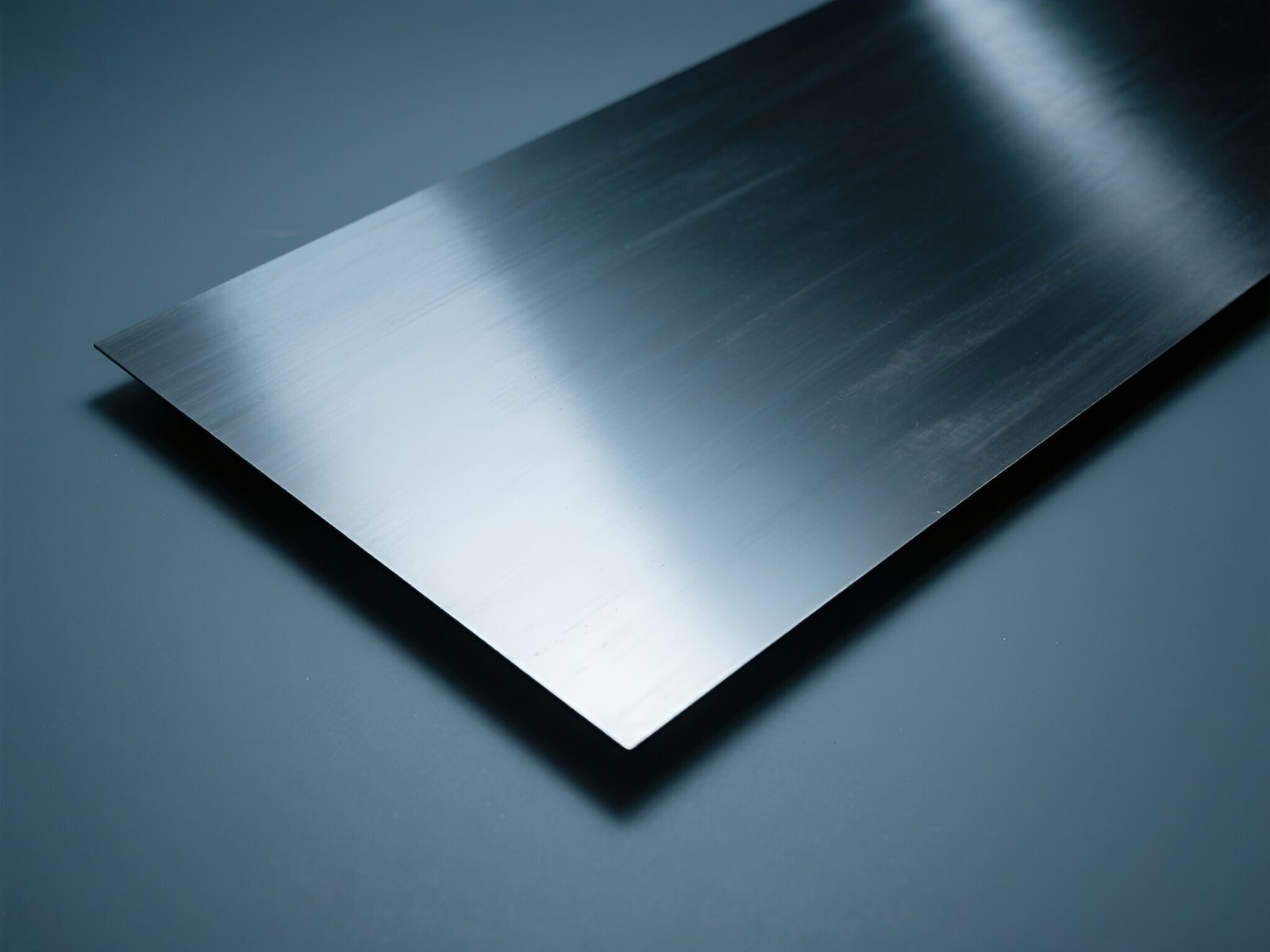

Aluminum

carbon steel

copper

iron

stainless steel

gold

Laser Marking Machine FAQ

The laser marking machine can mark on metals, plastics, glass, ceramics, wood, leather, and many other materials, making it suitable for various industries.

The fiber laser marking machine is ideal for metals and hard plastics, UV laser marking is perfect for delicate materials like glass and plastics, while CO₂ laser marking machines are best for non-metals such as wood and leather.

No, laser markings are permanent. The process alters the material surface, making marks scratch-resistant, corrosion-proof, and long-lasting.

No, laser marking machines are non-contact systems that don’t require ink or cutting tools, resulting in low operating costs and almost no consumables.

Fiber laser marking machines are virtually maintenance-free, while UV and CO₂ systems only need occasional lens cleaning. Overall, maintenance costs are minimal.

Consider your material type, marking precision, production volume, and budget. Contact us, and our experts will help you choose the best laser marking solution for your business.

Consider your material type, marking precision, production volume, and budget. Contact us, and our experts will help you choose the best laser marking solution for your business.

Laser markings are permanent and resistant to wear, corrosion, and fading, making them ideal for branding and industrial applications.

Why Choose JOYLASER?

Over 10 years of laser manufacturing experience, CE/FDA certified, trusted by clients in 50+ countries.

Fast delivery, expert support, and customized laser solutions for your industry needs.

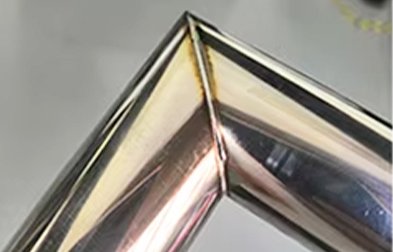

Laser Welding Machine Samples & Welding Examples

111-1024x458.png)