100W MOPA Galvo Laser Welding Machine

The 100W MOPA Galvo Laser Welding Machine combines a tunable pulse laser source with a high-speed galvo scanner, delivering precise, spatter-free welds for metals like copper, aluminum, and stainless steel. Designed for delicate applications such as battery tabs, medical devices, and electronics packaging, it ensures minimal heat impact and seamless integration with automated production lines.

This is popup title

You don't need to waste your time and money anymore.

Description

Joylaser 100W MOPA Galvo Laser Welding Machine Product Introduction

The 100W MOPA Galvo Laser Welding Machine integrates a tunable-pulse MOPA fiber laser and a high-speed galvanometer scanning system, making it ideal for micro-welding applications in electronics, high-reflectivity metals, and precision components. Compared to traditional laser welders, it offers enhanced pulse flexibility, minimized heat-affected zones, and ultra-clean weld seams without spatter.

It supports multiple welding modes—spot welding, seam welding, and hermetic sealing—and is compatible with automated production lines. With 30%+ production efficiency improvement, it’s widely used in medical devices, battery tabs, 3C electronics, and fine metal parts.

100W MOPA Galvo Laser Welding Machine Core Strengths

Spatter-free welding of reflective metals

Adjustable pulse width for versatile welding tasks

High-speed galvo scanner for increased throughput

Ultra-precise control with minimal heat-affected zone

Seamless integration with automation systems

100W MOPA Galvo Laser Welding Machine Technical Parameters

| Specification | Value |

|---|---|

| Laser Type | MOPA Fiber Laser |

| Laser Power | 100W |

| Wavelength | 1064nm |

| Welding Mode | Spot Welding, Seam Welding, Fill Welding |

| Pulse Width | 2~500ns (Adjustable) |

| Repetition Frequency | 1~1000kHz |

| Galvo Scanner Type | High-Speed Digital Galvo Head |

| Focus Spot Diameter | Approx. 0.1~0.2mm (depending on lens) |

| Control System | Industrial PC with Professional Welding Software |

| Cooling Method | Water Cooling |

| Laser Output | Fiber Output |

| Fiber Length | 5 meters (customizable) |

| Power Supply | AC220V ±10%, 50/60Hz |

| Supported Materials | Stainless Steel, Copper, Aluminum, Nickel, Titanium and Alloys |

| Automation Interface | Supports PLC / IO Interface |

| Operating Temperature | 15℃~35℃ |

100W MOPA Galvo Laser Welding Machine Application Scenarios

Battery tab and flexible connector welding

Medical-grade stainless steel micro-pipe welding

Electronic component hermetic sealing

Precision sensor and inductor welding

Fine metal wire and ribbon welding

Jewelry and watch micro-welding

100W MOPA Galvo Laser Welding Machine Demo

This video showcases the JOYLASER 100W MOPA Galvo Laser Welding Machine delivering high-precision welding on micro metal parts. Equipped with a MOPA fiber laser and high-speed galvo scanner, it enables non-contact, fine welding with smooth seams and minimal heat-affected zones.

Ideal for thin stainless steel, aluminum, copper, and nickel alloys, it’s widely used in electronics, sensors, medical devices, and optical components. Compact design with path import and platform integration ensures efficient, accurate production.

100W MOPA Galvo Laser Welding Machine Customer Cases

Case 1: Chinese Electronics Manufacturer

This client used the 100W MOPA Galvo Laser Welding Machine for battery tab welding in smartphones. The welds were stable and spatter-free, significantly improving product yield. The high-speed galvo scanner combined with adjustable pulse technology increased welding speed by over 30% compared to traditional methods, while minimizing heat-affected zones to prevent battery deformation and performance loss. The client reported improved automation and reduced labor costs.

Case 2: European Medical Device Company

A European medical device manufacturer used the laser welder for micro welding of precision stainless steel instruments, ensuring weld strength and aesthetic quality. The pulse width adjustment feature allowed handling materials of various thicknesses, achieving high-precision and non-destructive welds, greatly enhancing product reliability. The client praised the machine for its ease of use and low maintenance, becoming a key production asset.

Case 3: North American New Energy Battery Manufacturer

A leading North American new energy battery company utilized the 100W MOPA Galvo Laser Welding Machine for fast welding of battery tabs and modules. The laser welder enabled spatter-free welding of highly reflective copper and aluminum materials, with weld strength meeting automotive industry standards. The client reported the machine helped increase production capacity, improve product consistency, and significantly shorten delivery times.

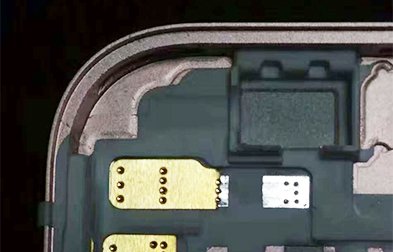

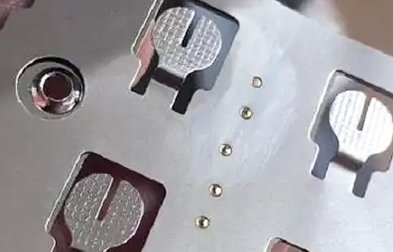

100W MOPA Galvo Laser Welding Machine Welding Examples

Joylaser 100W MOPA Galvo Laser Welding Machine FAQ

Q1: What materials can the 100W MOPA Galvo Laser Welding Machine weld?

A: The 100W MOPA Galvo Laser Welding Machine is suitable for metals like stainless steel, aluminum, copper, titanium, nickel, and their alloys. It’s especially effective for high-reflectivity materials.

Q2: What are the advantages of the 100W MOPA Galvo Laser Welding Machine compared to traditional laser welders?

A: It features adjustable pulse width, high-speed galvo scanning, and micro-welding capabilities with minimal heat impact—ideal for electronics, battery, and medical applications.

Q3: Can the 100W MOPA Galvo Laser Welding Machine be integrated into an automated production line?

A: Yes. It supports PLC and IO interfaces for seamless integration with robots, vision systems, and robotic arms in automated welding lines.

Q4: How is the welding depth and speed of the 100W MOPA Galvo Laser Welding Machine?

A: It offers a welding speed of several tens of centimeters per minute and a depth typically ranging from 0.2–0.8mm, depending on the material and settings.

Q5: Can non-professional operators use this laser welding machine?

A: Yes. The machine comes with a user-friendly interface in both Chinese and English, with preset welding parameters for easy operation after basic training.

Q6: Is the 100W MOPA Galvo Laser Welding Machine expensive to maintain?

A: No, it’s low-maintenance. The laser source has a 100,000-hour lifespan, requiring only regular cleaning, coolant replacement, and dust-free operation.

Q7: Can the 100W MOPA Galvo Laser Welding Machine be customized?

A: Yes, customization is available for worktables, optics, and software. OEM options and integration with automation systems are supported.

111-1024x458.png)