Description

1500W Mold Laser Welding Machine Product Introduction

The 1500W mold laser welding machine utilizes advanced fiber laser technology, combining high power output with precise pulse control, designed specifically for welding and repairing complex mold structures. It supports welding of various metals, including mold steel, stainless steel, aluminum alloy, and copper alloy, meeting diverse industrial mold repair needs. Its high-speed welding capability significantly improves repair efficiency, while the low heat-affected zone minimizes welding deformation, ensuring weld quality and mold precision. Equipped with an intelligent control system and high-resolution visual positioning, it offers easy operation and stable welding performance. Widely applied in injection molds, die-casting molds, stamping molds, and industrial part repairs.

1500W Mold Laser Welding Machine Core Advantages

High-power laser output meets the demands of large and complex mold welding

Precise pulse control ensures aesthetically pleasing welds with excellent mechanical properties

Multi-metal compatibility supports steel, aluminum, copper, and more

Low heat-affected zone design minimizes welding deformation

Intelligent visual-assisted positioning enhances welding accuracy and efficiency

High-speed welding significantly improves repair productivity

1500W Mold Laser Welding Machine Application Scenarios

1.Precision Mold Repair

Suitable for repairing micro-cracks, edges, and worn areas of injection molds, die-casting molds, and stamping molds.

2.Automotive Mold Maintenance

Ideal for welding high-strength steel and aluminum alloy molds used in automotive manufacturing.

3.Electronics and Connector Molds

Used in repairing small precision molds for plastic connectors, sockets, and electronic housing molds.

4.Medical Device Molds

Applicable to repairing fine details of stainless steel or titanium molds used in medical equipment production.

5.Rubber and Silicone Molds

Suitable for mold repair in the production of seals, gaskets, and other rubber parts.

6.Household Appliance Mold Repair

Efficient in fixing molds for appliances such as washing machines, refrigerators, and kitchen equipment.

1500W Mold Laser Welding Machine Welding Demo

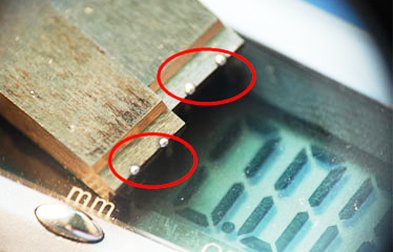

In this welding demo, the 1500W mold laser welder delivers stable high-energy laser output for precise repair of surface cracks, chipped edges, and localized wear on molds. Utilizing advanced fiber laser technology and precision control, it ensures focused heat input, smooth welding, and minimal distortion—leaving mold surfaces clean and nearly polish-free. Perfectly suited for common steel types like P20, NAK80, and H13, it excels in repairing plastic molds, die-casting molds, and metal stamping molds. With its ergonomic interface and HD microscope system, it enables accurate welding even on intricate details, making it an efficient solution for mold maintenance and on-site rework.

1500W Mold Laser Welding Machine Technical Specifications

| Parameter | Specification |

|---|---|

| Laser Power | 1500W |

| Laser Type | Fiber Laser (QCW / CW optional) |

| Wavelength | 1070 nm |

| Pulse Width Range (QCW type) | 0.2 – 50 ms |

| Pulse Frequency Range (QCW type) | 1 – 500 Hz |

| Continuous Mode (CW type) | Adjustable up to 1500W |

| Spot Size | 0.1 – 3 mm adjustable |

| Positioning Accuracy | ±0.01 mm |

| Repeat Positioning Accuracy | ±0.005 mm |

| Cooling Method | Water Cooling |

| Power Supply | 220V / 380V, 50/60Hz |

| Control System | Touchscreen + Joystick / PC + CNC optional |

| Working Table | XYZ Precision Motion Platform (customizable) |

| Axis Travel | X/Y/Z Axis: 300mm / 300mm / 200mm (customizable) |

| Shielding Gas | Argon / Nitrogen |

| Observation System | Microscope + CCD Camera |

| Welding Depth | ≤2.5 mm (depending on material) |

| Machine Dimensions | Approx. 1200mm × 800mm × 1600mm |

1500W Mold Laser Welding Machine Customer Cases

Industry: Precision Mold Manufacturing

Location: Germany

Customer Profile: Leading plastic injection mold manufacturer

Application:

The customer used the 1500W mold laser welding machine to repair high-precision injection molds made primarily of P20 and H13 tool steels. Traditional TIG welding caused excessive heat, resulting in mold deformation and increased polishing time.

Results:

Achieved ultra-fine weld seams less than 0.2 mm, maintaining mold shape and tolerance.

Reduced thermal stress and cracking due to localized heat control using QCW mode and 1500W laser power.

Post-weld grinding and polishing time cut by 40 percent.

Extended mold service life by enabling multiple repair cycles of expensive mold cores.

Customer Feedback:

“The 1500W laser welder has revolutionized our mold repair process. Heat deformation is no longer a concern, and our maintenance team can perform precision repairs efficiently in-house.”

— Technical Director, German Mold Manufacturer

1500W Mold Laser Welding Machine Application Scenarios

1500W Mold Laser Welding Machine FAQ

Q1: What materials can the 1500W laser welding machine weld?

A1: It can weld various metals including stainless steel, carbon steel, aluminum alloys, copper, titanium, and mold tool steels such as H13 and P20.

Q2: What is the maximum welding thickness?

A2: The machine can weld metal thicknesses up to approximately 5 mm in a single pass, depending on the material and welding parameters.

Q3: What types of welding modes does the machine support?

A3: It supports QCW (quasi-continuous wave) pulse welding and continuous wave (CW) welding modes for different application needs.

Q4: How precise is the welding?

A4: The welding accuracy is within ±0.01 mm, ideal for precision mold repairs and micro welding.

Q5: What cooling method is used?

A5: The machine uses a water-cooling system to maintain stable laser operation and prevent overheating.

Q6: Is training provided for operating the laser welder?

A6: Yes, professional training and technical support are provided to ensure efficient and safe machine operation.

111-1024x458.png)