2000W Mold Laser Welding Machine

The 2000W mold laser welding machine is designed for the mold industry, featuring high-power laser output and excellent welding precision, ideal for fast repair and fabrication of various metal molds.

This is popup title

You don't need to waste your time and money anymore.

Description

2000W Mold Laser Welding Machine Product Introduction

The 2000W Mold Laser Welding Machine utilizes advanced fiber laser technology, specially designed for efficient and precise mold welding and repair. Equipped with powerful laser output, it rapidly achieves deep welding with strong and aesthetically clean weld seams. Featuring an intelligent user-friendly interface, the machine simplifies operation, significantly reducing labor difficulty and boosting productivity. Its high stability and excellent thermal input control effectively minimize welding deformation, ensuring dimensional accuracy and prolonging mold service life. With 2000W power, it is suitable for various metal materials including steel, stainless steel, aluminum alloys, and other mold metals, meeting the rigorous demands of mold repair across multiple industries. Whether for mold fabrication, maintenance, or complex restoration, this laser welding machine delivers high-quality, reliable welds, making it an indispensable tool in the mold processing field.

2000W Mold Laser Welding Machine Core Advantages

High-power laser output ensures welding depth and strength

Precise laser beam control enables fine welding details

Automated control interface reduces manual operation complexity

Efficient cooling system ensures stable long-term operation

Multiple welding modes adapt to different materials and needs

2000W Mold Laser Welding Machine Technical Specifications

| Parameter | Specification |

|---|---|

| Laser Power | 2000W |

| Laser Type | Fiber Laser |

| Wavelength | 1064 nm |

| Welding Mode | Continuous / Pulsed |

| Max Welding Speed | Up to 1200 mm/min |

| Spot Diameter | 0.1 – 0.3 mm |

| Cooling Method | Water Cooling |

| Power Supply | AC 220V ±10%, 50/60 Hz |

| Control System | Digital Touchscreen Interface |

| Operating Temperature Range | 10°C – 40°C |

| Dimensions (L×W×H) | 1200 × 800 × 1500 mm |

| Weight | Approx. 200 kg |

| Applicable Materials | Steel, Stainless Steel, Aluminum, Copper, etc. |

| Safety Protection | Laser Safety Goggles & Emergency Stop |

2000W Mold Laser Welding Machine Application Scenarios

Mold Repair: Rapidly repair defects on injection, die-casting, and stamping molds

Mold Manufacturing: Efficiently weld mold components to improve quality

Hardware Processing: Welding and assembly of metal parts

Automotive Parts Production: Welding precise automotive molds and components

Electronics Manufacturing: Welding small metal parts and connectors

2000W Mold Laser Welding Machine Welding Demo

In this demo, the 2000W mold laser welding machine delivers precise repairs on mold surface cracks, corner collapses, and worn areas—demonstrating excellent control and consistent weld quality. Powered by a high-performance fiber laser, it offers moderate penetration and a minimal heat-affected zone, making it ideal for fast repairs on steel molds such as P20, 718, and H13. The system features microscopic operation and intelligent pulse control, enabling smooth, accurate welds even on fine structures. With little or no post-processing required, it’s widely used in plastic, die-casting, and precision metal molds—an essential tool for restoring, maintaining, and extending mold life with minimal downtime.

2000W Mold Laser Welding Machine Customer Case Study

| Country | Client Type | Application Scenario | Results |

|---|---|---|---|

| Germany | Stainless Steel Kitchenware Manufacturer | Seamless welding between sink edge and basin body | After adopting the 2000W laser welding machine, achieved deformation-free continuous welding with smooth weld seams. Product qualification rate increased by 15%, and production efficiency improved by 30%. |

| USA | New Energy Battery Manufacturer | Battery pack shell and tab welding | Replacing traditional resistance welding, the weld is firmer with accurate energy control. Heat-affected zone is minimized, improving thermal stability. Pass rate reached 98.7%. |

| China | Automotive Parts Supplier | Structural welding of seat rails and door hinges | Integrated into automated lines, the 2000W laser welding machine shortened processing time by 40%. Weld strength meets OEM standards with high consistency. |

| Japan | Precision Sheet Metal Fabricator | Precision welding of aluminum alloy enclosures | Using a high-speed welding head with a 2000W fiber laser, the weld is flat without grinding, with minimal distortion. Customer reports a 95% replacement rate for traditional methods. |

| India | Industrial Equipment Manufacturer | Frame and panel welding of electric control boxes | The 2000W handheld laser welder significantly increased welding speed while reducing rework rate. Supports different thicknesses of stainless and carbon steel sheets. |

| Brazil | Agricultural Machinery Manufacturer | Welding of thick metal parts | Deep penetration welding achieved with 2000W machine. Weld strength is high, resistant to impact and vibration. Welding efficiency increased by about 40%. |

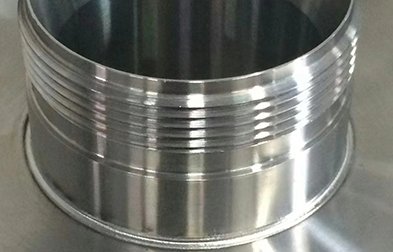

2000W Mold Laser Welding Machine Welding Example

2000W Mold Laser Welding Machine FAQ

Q1: What metal materials are suitable for the 2000W laser welding machine?

A1: Suitable for welding carbon steel, stainless steel, aluminum alloy, copper, and other common metals.

Q2: Does the machine support automatic welding programs?

A2: Yes, equipped with intelligent control system for automated welding and parameter adjustment.

Q3: Is maintenance complicated?

A3: The machine is designed for easy maintenance, with detailed manuals and after-sales support.

Q4: What is the maximum welding thickness?

A4: Up to 6mm thick metal molds can be welded.

Q5: Can the machine be used outside the mold industry?

A5: Yes, it suits various industrial welding needs but is optimized for mold welding.

111-1024x458.png)