200W MOPA Galvo Laser Welding Machine

200W MOPA Galvo Laser Welding Machine is designed for ultra-fast, high-precision micro-welding. It handles thin metals and reflective materials like copper and aluminum with exceptional control. Ideal for electronics, battery tabs, and precision components.

This is popup title

You don't need to waste your time and money anymore.

Description

200W MOPA Galvo Laser Welding Machine Product Introduction

ChatGPT 说:

The 200W MOPA Galvo Laser Welding Machine is an advanced system specifically designed for high-precision, high-speed micro-welding tasks. It integrates a 200W MOPA fiber laser with a high-resolution galvo scanning system, enabling precise control over pulse waveform and energy distribution. It can stably weld highly reflective materials such as copper and aluminum, producing clean welds without spatter.

With adjustable pulse width and a frequency of up to 2000 kHz, this machine flexibly meets the demanding requirements of battery manufacturing, electronic components, medical devices, and other high-standard applications. It performs exceptionally well in automated production lines, supporting multiple industrial protocols and software integrations to easily achieve intelligent manufacturing needs.

200W MOPA Galvo Laser Welding Machine Core Advantages

The JOYLASER 200W MOPA Galvo Laser Welding Machine offers exceptional precision and processing flexibility. Equipped with a MOPA fiber laser source featuring adjustable pulse width, it delivers accurate micro-welding and intricate contour shaping with minimal heat-affected zones—ideal for sensitive and small metal components.

Its high-speed galvo system enables non-contact scanning for faster, more consistent welds. Compatible with stainless steel, aluminum, copper, and nickel alloys, this machine is widely used in 3C electronics, medical devices, optical communications, and hardware manufacturing. Supporting path import, multi-axis motion, and automation integration, it’s a powerful solution for high-precision, high-efficiency welding needs.

200W MOPA Galvo Laser Welding Machine Application Scenarios

Battery tab and busbar welding

Micro-welding in medical device production

Component welding in electronics

High-precision automation welding

200W MOPA Laser Welding Machine Demo

In this demo, the JOYLASER 200W MOPA Galvo Laser Welding Machine precisely welds micro metal components with high accuracy. It utilizes adjustable MOPA pulse widths and high-speed galvo scanning, ideal for small seams, thin walls, and complex contours. Minimal heat input ensures no deformation or edge burns.

The result is clean, spatter-free welds requiring no polishing. Compatible with stainless steel, copper, aluminum, and nickel alloys, it’s widely used in 3C electronics, medical devices, hardware, and fiber optic components.

With support for auto path import and multi-axis motion, this system boosts productivity and precision—perfect for high-requirement, repeatable welding tasks.

200W MOPA Laser Welding Machine Technical Parameter

| Parameter | Specification |

|---|---|

| Laser Source | MOPA Fiber Laser |

| Power Output | 200W |

| Frequency Range | 1–2000 kHz |

| Pulse Width | 2–500 ns adjustable |

| Galvo Scanner | High-speed, high-accuracy |

| Cooling Method | Water cooling |

| Software System | PC + Galvo Control Software |

| Interface Options | IO, Ethernet, RS232, Custom Integration |

200W MOPA Laser Welding Machine Case Study

• A leading German battery module manufacturer adopted the 200W MOPA Galvo Laser Welding Machine for precision battery tab welding. This integration resulted in a 30% increase in production efficiency and a significant reduction in defect rates, greatly enhancing overall product quality and consistency.

• A prominent Chinese 3C electronics manufacturer incorporated the machine into their copper micro-welding production line. This upgrade enabled precise quality control at the micro-level and seamless integration with their MES system, improving traceability and manufacturing automation.

• A top-tier U.S. medical device company utilizes the 200W MOPA Galvo Laser Welding Machine for assembling high-end surgical instruments. The machine delivers clean, spatter-free welds with excellent traceability, earning widespread praise from customers for reliability and superior performance.

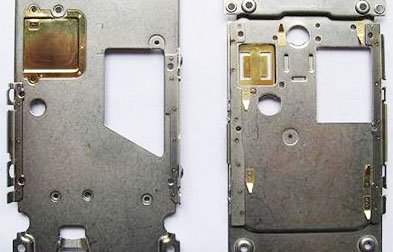

200W MOPA Laser Welding Machine Welding Example

200W MOPA Laser Welding Machine Welding Example FAQ

1. What materials can the 200W MOPA Galvo Laser Welding Machine weld?

It is suitable for aluminum, copper, stainless steel, titanium alloys, and other reflective or precision metal

2. What advantages does the 200W MOPA Galvo Laser Welding Machine offer over traditional pulse welders?

It offers higher frequency range, finer pulse control, and more precise energy management.

3.Can the 200W MOPA Galvo Laser Welding Machine be integrated with automated production lines?

Yes, it supports IO, RS232, and network protocols for seamless MES and PLC system integration.

4.Is the 200W MOPA Galvo Laser Welding Machine suitable for high-reflective materials like copper?r?

Yes, its MOPA characteristics are optimized for welding reflective metals with clean seams.

5.Is the 200W MOPA Galvo Laser Welding Machine difficult to operate?

Not at all. It offers a user-friendly bilingual interface and requires only short-term operator training.

111-1024x458.png)