Description

Joylaser 3‑in‑1 Laser Welding Machine Product Introduction

The 3-in-1 laser welding machine is an advanced multifunctional laser system that seamlessly integrates laser welding, laser cleaning, and laser cutting into one compact and flexible unit. Using cutting-edge fiber laser technology and a smart control interface, operators can switch between modes simply by changing the nozzles — no need to switch machines or systems.

Designed for maximum efficiency and versatility, this machine is ideal for applications involving metal joining, surface cleaning (such as rust, paint, and oil removal), and precision sheet metal cutting. Its compact body fits well in workshops with limited space, making it an excellent choice for small and medium-sized manufacturers that need to handle various processing tasks.

With optional air- or water-cooling configurations, continuous wave or pulsed laser modes, and integrated safety protection, the 3-in-1 system ensures high-precision performance with minimal maintenance. Its intuitive touchscreen interface and intelligent power management make it easy for even non-experts to operate, increasing productivity while reducing operational cost.

3‑in‑1 Laser Welding Machine Core Advantages

Three-in-One Versatility

Integrates laser welding, laser cleaning, and laser cutting functions in a single device, providing unmatched flexibility for diverse industrial applications.Plug-and-Play Design

User-friendly interface and integrated control system make operation simple, requiring minimal training and setup time.Energy Saving and Eco-Friendly

Low power consumption and non-contact processing reduce energy use and material waste, making it an environmentally responsible choice.Wide Material Compatibility

Suitable for welding, cleaning, and cutting stainless steel, carbon steel, aluminum, copper, galvanized sheet, and more.Compact and Portable

Integrated compact design makes it ideal for small workshops, on-site repairs, or mobile operations.- Customizable Power Options

Available in various power configurations (1000W/1500W/2000W/3000W) to meet different processing needs.

3‑in‑1 Laser Welding Machine Application Scenarios

Metal Fabrication: Welding, cutting, and cleaning of metal parts and components with precision.

Automotive Industry: Repairing and manufacturing automotive parts such as frames, radiators, and battery cases.

Electronics: Welding and trimming delicate electronic components and housings.

- Kitchenware Manufacturing: Seamless welding and cutting of stainless steel kitchen appliances and utensils.

Advertising and Signage: Cutting and welding metal signs and advertising materials.

Shipbuilding and Heavy Industry: Efficient cleaning and welding of large metal structures and parts.

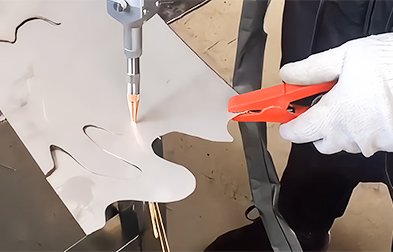

3-in-1 Laser Welding Machine Welding Demo

This demo highlights the all-in-one power of the 3-in-1 handheld laser welder, combining welding, cutting, and cleaning in a single compact unit. Powered by fiber laser technology, it easily handles carbon steel, stainless steel, and aluminum with clean, deep welds. Switch modes to perform precision cutting or non-contact surface cleaning—ideal for weld prep, rust removal, or oxide cleaning. With ergonomic design and intelligent control, it ensures comfort and safety during use. Widely used in hardware manufacturing, sheet metal processing, and equipment maintenance, this multi-function tool boosts productivity and reduces equipment investment.

3‑in‑1 Laser Welding Machine Technical Specifications

| Parameter | Description |

|---|---|

| Laser Type | Fiber Laser |

| Laser Power | 3000W |

| Wavelength | 1064 nm |

| Pulse Width Range | 0.1 ms – 50 ms |

| Pulse Frequency | 1 Hz – 1000 Hz |

| Cooling Method | Air Cooling / Water Cooling |

| Welding Speed | Up to 1200 mm/min |

| Focus Spot Size | 0.1 mm – 0.3 mm |

| Power Supply | AC 220V ±10%, 50/60 Hz |

| Machine Weight | Approx. 200 kg |

| Machine Dimensions | 1200 mm x 800 mm x 1500 mm |

| Control System | CNC Control / PC Interface |

| Protection Gas | Argon / Nitrogen (optional) |

3‑in‑1 Laser Welding Machine Customer Cases

1.CN Kitchen Appliance Maker Laser cleaning and cutting of stainless steel panels Significantly improved surface finish and cutting precision, reducing manual rework time by 30%.

2.USA Automotive Manufacturer Welding car frame parts and components Achieved high-speed, precise welding with reduced heat distortion, improving production efficiency by 25%.

3.South Korea Furniture Manufacturer Welding and cutting metal furniture parts Combined welding, cutting, and cleaning functions streamlined production, cutting lead time by 20%.

3‑in‑1 Laser Welding Machine Welding Example

Joylaser 3‑in‑1 Laser Welding Machine FAQ

Q1: What is 3-in-1 laser welding machine?

A1: The 3-in-1 laser welding machine integrates the three functions of laser welding, laser cutting and laser cleaning, which can meet a variety of metal processing needs and improve productivity and processing quality.

Q2: What materials is the 3-in-1 laser welder suitable for?

A2: The equipment is suitable for a variety of metal materials, such as stainless steel, carbon steel, aluminum alloys, copper and titanium alloys, etc. It is especially suitable for high-precision welding and processing of thin plates and complex workpieces.

Q3: Is it complicated to operate the equipment? Does it require professional training?

A3: The equipment is equipped with a user-friendly human-machine interface (HMI), which is simple and intuitive to operate. Basic training is recommended to ensure proper use and maintenance to prolong the life of the equipment and guarantee welding results.

Q4: What are the main advantages of the 3-in-1 laser welding machine?

A4: Multi-functional integration of the equipment saves space in the workshop; high-precision welding and cutting; efficient cleaning process to improve the surface quality of the products; energy saving and environmental protection, safe operation.

Q5: How often is the equipment maintained? Does it require special maintenance?

A5: Maintenance of the equipment is simple. It is recommended to clean the optical lens, check the cooling system and gas supply regularly to keep the equipment in good condition. Specialized technicians are recommended for maintenance of special parts.

Q6: What is the power range of the 3-in-1 laser welding machine?

A6: The power of the equipment can be customized according to customer’s needs, the common power range is from 1000W to 3000W, which meets the welding and cutting needs of different industrial applications.

Q7: How to ensure the after-sales service of the equipment?

A7: We provide worldwide after-sales support, including remote technical guidance, on-site maintenance and spare parts supply, to ensure the long-term stable operation of customers’ equipment.

111-1024x458.png)