300W MOPA Galvo Laser Welding Machine

The 300W MOPA Galvo Laser Welding Machine combines a high-speed scanning system with a MOPA fiber source, delivering stable performance and flexible pulse control. Ideal for efficient, precision welding of electronics, fine hardware, sensors, and thin-walled components.

This is popup title

You don't need to waste your time and money anymore.

Description

300W MOPA Galvo Laser Welding Machine Product Introduction

The 300W MOPA Galvo Laser Welding Machine is an advanced micro-welding system combining a 300W pulsed MOPA fiber laser with a high-speed galvanometer scanner. Designed for high-speed, non-contact precision welding, it is especially effective for reflective and delicate metals such as copper, aluminum, and stainless steel.

With adjustable pulse widths (2–500ns) and frequencies up to 2000kHz, this system delivers exceptional control over energy distribution, allowing for precise, clean, and consistent welds—even on ultra-thin materials. Its compact structure, easy software integration, and compatibility with automation systems make it a perfect fit for modern intelligent manufacturing environments.

300W MOPA Galvo Laser Welding Machine Core Advantages

Adjustable pulse width for diverse process requirements

High-frequency galvo scanner for fast and accurate welding

Stable energy output for reflective materials like copper and aluminum

Micro-welding with clean seams, no spatter, and minimal fumes

Compatible with automation protocols for smart production integration

300W MOPA Galvo Laser Welding Machine Application Scenarios

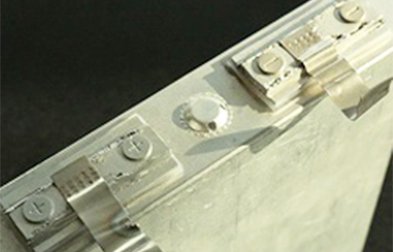

Battery tab and aluminum busbar welding

Clean micro-welding in medical device production

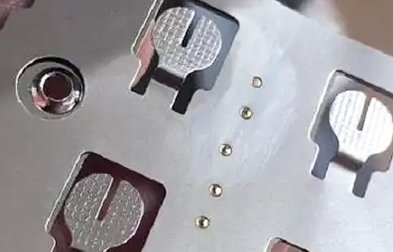

Micro-welding of mobile phone PCBs and electronic connectors

Automated welding for precision metal component assembly

300W MOPA Galvo Laser Welding Machine Demo

This demo features the JOYLASER 300W MOPA Galvo Laser Welding Machine delivering high-speed precision welds on micro-scale metal parts. The MOPA laser source offers adjustable pulse width and high peak power, making it perfect for thin walls, small joints, and fine contours with minimal heat-affected zones.

It ensures clean seams without post-processing and is compatible with stainless steel, copper, aluminum, and nickel. Ideal for 3C electronics, precision hardware, medical components, and sensor welding.

The system supports path import, fixture integration, and rapid scanning—compact, flexible, and built for demanding applications.

300W MOPA Galvo Laser Welding Machine Technical Parameters

| Parameter | Specification |

|---|---|

| Laser Source | MOPA Fiber Laser |

| Maximum Output Power | 300W |

| Frequency Range | 1–2000 kHz |

| Pulse Width | 2–500 ns adjustable |

| Galvo Scanner | High-speed galvo scan system |

| Cooling Method | Water cooling |

| Software System | Industrial PC + Galvo control system |

| Interface Options | IO / Ethernet / RS232 / Customizable |

300W MOPA Galvo Laser Welding Machine customer cases

A Japanese Power Battery Manufacturer:

Replaced traditional YAG welding with the 300W MOPA Galvo Laser Welder for battery tab applications. The pass rate increased from 92% to 98.5%, and daily production per line improved by 20%.

A U.S. High-End Medical Device Manufacturer:

Used the machine for precision welding of titanium microsurgical instruments. It met strict requirements for burr-free joints, traceability, and zero thermal deformation.

A Leading Chinese 3C Electronics Enterprise:

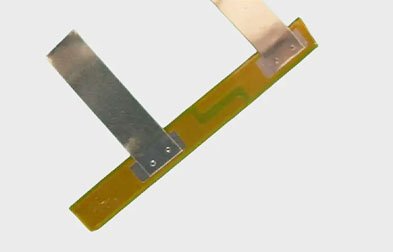

Deployed on FPC metal tab welding lines, leveraging high-speed multi-point galvo scanning. Cycle time was reduced by 40%, and overall line stability significantly improved.

300W MOPA Galvo Laser Welding Machine Welding Example

300W MOPA Galvo Laser Welding Machine FAQ

Q1: What materials can the 300W MOPA Galvo Laser Welder weld?

It is suitable for aluminum, copper, stainless steel, titanium alloys, and other reflective or thick metals

Q2:What makes the 300W MOPA Galvo Laser Welding Machine unique?

It features high power, adjustable pulse width, and precise energy control for more complex welding tasks.

Q3:Can it be integrated into automated lines?

Yes, it supports MES/PLC integration via IO, network, and RS232 protocols.

Q4:Is it suitable for high-reflectivity materials like copper?

Absolutely. MOPA characteristics ensure precise heat control in reflective metals like copper.

Q5: Is it difficult to operate?

No. The user interface is clean, bilingual, and suitable for quick training and deployment.

111-1024x458.png)