Air-Cooled Handheld Laser Welding Machine

The air-cooled handheld laser welding machine is a highly efficient and user-friendly solution for metal welding. With an air-cooling system, it eliminates the need for complex water cooling, ensuring easier maintenance and more stable performance. Its compact design and flexible operation allow seamless welding of stainless steel, carbon steel, aluminum alloys, and more. Delivering smooth, precise welds with superior speed, it is an ideal choice for small and medium-sized factories as well as diverse production requirements.

This is popup title

You don't need to waste your time and money anymore.

Description

Air-Cooled Handheld Laser Welding Machine Product Introduction

The air-cooled handheld laser welding machine integrates portability, efficiency, and precision in one advanced device. Utilizing cutting-edge air cooling technology, it eliminates the complexity of traditional water cooling systems, significantly enhancing operational flexibility and onsite adaptability. Equipped with a high-quality fiber laser source, it is ideal for welding and repairing stainless steel, aluminum alloy, carbon steel, copper, and other metals, widely used in mold manufacturing, automotive parts, kitchenware, jewelry, and industrial fabrication.

Air-Cooled Handheld Laser Welding Machine Core Advantages

No Water Cooling Required

Equipped with an advanced air-cooled system, eliminating the need for bulky and maintenance-heavy water chillers, making the machine more portable and easier to operate on-site.Lightweight and Portable

Compact design and reduced weight enable effortless handheld operation, ideal for mobile welding tasks and confined working environments.High Welding Precision

Delivers a focused laser beam with minimal heat-affected zones, producing smooth, clean, and aesthetically pleasing weld seams with excellent structural integrity.Energy Efficient and Low Maintenance

Air cooling reduces power consumption and system complexity, lowering operational costs and minimizing downtime.Versatile Metal Compatibility

Capable of welding various metals including stainless steel, aluminum, carbon steel, copper, and their alloys, suitable for diverse industrial applications.

Air-Cooled Handheld Laser Welding Machine Technical Specifications

| Technical Parameters | Specification |

|---|---|

| Laser Type | Fiber Laser |

| Laser Power | 500W / 1000W / 1500W (optional) |

| Cooling Method | Air-Cooled |

| Wavelength | 1070 nm |

| Pulse Frequency | 1 Hz – 20 kHz |

| Welding Spot Size | 0.1 mm – 0.3 mm |

| Peak Power | Up to 10 kW |

| Duty Cycle | 100% |

| Power Supply | AC 220V ±10%, 50/60 Hz |

| Weight | Approx. 35 kg or above |

| Dimensions (L × W × H) | 450 mm × 150 mm × 200 mm |

| Control Interface | Touch Screen / Remote Control |

| Welding Speed | Up to 10 mm/s |

| Applicable Materials | Stainless Steel, Aluminum, Carbon Steel, Copper, Alloys |

Air-Cooled Handheld Laser Welding Machine Application Scenarios

Automotive Industry

Welding of automotive parts such as engine components, chassis, and exhaust systems with high precision and durability.Metal Fabrication and Repair

Ideal for repairing molds, metal tools, and machinery parts, extending their service life and maintaining structural integrity.Kitchenware Manufacturing

Seamless welding of stainless steel and aluminum kitchen utensils, sinks, and cookware with clean and strong welds.Advertising and Signage

Welding of metal letters, signs, and decorative elements with fast processing and excellent finishing.Electrical and Electronics

Assembly and welding of electronic components and enclosures requiring fine, stable weld seams.On-site and Mobile Welding

Portable design enables efficient welding in workshops, factories, or directly on-site for maintenance and assembly tasks.

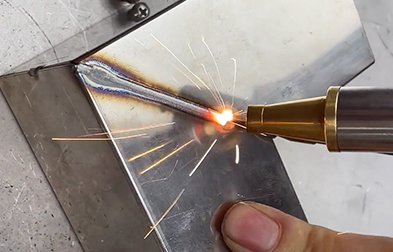

Air-cooled handheld laser welding machine welding Demo

In this demo, the air-cooled handheld laser welding machine demonstrates the perfect balance of portability and performance. Unlike traditional water-cooled systems, it features an integrated air-cooling design—eliminating the need for bulky chillers and reducing maintenance costs. The stable laser output enables clean, strong welds on stainless steel, carbon steel, and aluminum with minimal spatter and no post-polishing required. Compact and mobile, it’s perfect for hardware fabrication, pipe welding, electrical installations, and everyday repairs in small to medium-sized workshops. A smart, space-saving solution for efficient on-site welding!

Air-Cooled Handheld Laser Welding Machine Customer Cases

Country: Germany

Customer Type: Automotive Parts Manufacturer

Application: Welding stainless steel exhaust pipes and brackets

Result: After using the air-cooled handheld laser welding machine, welding efficiency increased by 40%, and welding seams became more precise and aesthetically pleasing, reducing rework rate.

Country: India

Customer Type: Kitchen Equipment Factory

Application: Welding stainless steel sinks and hoods

Result: The compact, portable design of the machine helped improve operation flexibility. Welding quality met export standards, and production costs dropped significantly due to reduced gas and electricity consumption.

Country: Mexico

Customer Type: Sheet Metal Fabricator

Application: Welding aluminum doors and windows

Result: With stable beam quality and minimal heat distortion, the client achieved high-quality results on reflective materials. The machine’s easy-to-learn interface reduced operator training time by 60%.

Air-Cooled Handheld Laser Welding Machine Welding Example

Air-Cooled Handheld Laser Welding Machine FAQ

Q1: What materials can the air-cooled handheld laser welding machine weld?

A1: This laser welder is suitable for stainless steel, carbon steel, galvanized sheet, aluminum, copper, and other common metals. It is especially ideal for thin sheet welding and high-precision joint seams.

Q2: Is it difficult to operate the handheld laser welding machine?

A2: No, the machine is designed for ease of use. It features a user-friendly control panel and supports quick training. Most operators can master the basics within a few hours.

Q3: What are the advantages of an air-cooled laser welder compared to water-cooled models?

A3: Air-cooled welders offer lower maintenance, easier mobility, and do not require a separate water chiller. They are ideal for small workshops or on-site operations where water cooling is not convenient.

Q4: What is the maximum welding thickness this machine can handle?

A4: Depending on material and power output, the air-cooled handheld laser welder can weld stainless steel up to 4mm, and carbon steel up to 5mm in a single pass.

Q5: Does the machine support continuous welding for long hours?

A5: Yes. Thanks to efficient thermal management and stable laser output, the machine supports continuous welding for extended periods without overheating.

Q6: Can I switch between welding and cleaning functions?

A6: If the model supports multifunction (e.g., 3-in-1 systems), it allows easy switching between welding, cleaning, and cutting by changing nozzles and selecting the desired mode on the screen.

Q7: What accessories are included in the package?

A7: The package typically includes welding nozzles, a fiber laser welding gun, protective goggles, a grounding wire, user manual, and optional wire feeder.

111-1024x458.png)