Swing-Arm Mold Fiber Laser Welding Machine

The Swing-Arm Mold Fiber Laser Welding Machine is engineered for the repair of large-scale molds and complex components requiring high-precision welding. Featuring extended working range, multi-axis motion, and high-energy fiber laser output, it enables deep, localized repair of stamping dies, injection molds, and aerospace structures with minimal heat impact, preserving material integrity and dimensional accuracy.

This is popup title

You don't need to waste your time and money anymore.

Description

Joylaser Swing-Arm Mold Fiber Laser Welding Machine Product Introduction

The Swing-Arm Mold Fiber Laser Welding Machine is a high-precision equipment specially engineered for mold repair and fine metal welding. Equipped with an imported fiber laser source and a flexible 360° swing-arm design, this machine allows the welding head to reach complex areas such as deep cavities, tight seams, and sharp mold edges with ease and accuracy.

This model excels in offering a concentrated energy beam with minimal heat-affected zones, ensuring low thermal distortion and high weld quality. It supports both continuous and pulsed welding modes, making it ideal for handling various metal materials with different thicknesses and welding requirements. The HD CCD camera system provides real-time visual monitoring of the weld spot, ensuring maximum accuracy and operator safety.

The working platform supports manual or electric lift adjustment, allowing for flexible handling of molds in different sizes. The user interface is intuitive, multilingual, and optimized for overseas clients, enabling quick learning and efficient operation. The industrial-grade water cooling system ensures stable performance during long hours of operation and prolongs the service life of the laser source.

Whether in mold factories, hardware processing plants, automotive parts repair shops, or high-end precision tool industries, the Swing-Arm Mold Fiber Laser Welding Machine from JOYLASER is a reliable solution that enhances welding quality, reduces post-processing, and boosts production efficiency.

Swing-Arm Mold Fiber Laser Welding Machine MachineKey Advantages

360° Adjustable Swing Arm: Easily adapts to complex mold structures

Stable Fiber Laser Source: Deeper penetration, faster welding, smooth finish

HD CCD Monitoring System: Real-time weld monitoring ensures accuracy

Multi-metal Compatibility: Supports stainless steel, aluminum, mold steel, etc.

Low Heat Distortion: Minimal heat-affected zone, ideal for precision repairs

Swing-Arm Mold Fiber Laser Welding Machine Application Scene

Injection mold crack repair

Corner welding in stamping molds

Defect repair in die-casting molds

Metal crack and pore patching

Swing-Arm Mold Fiber Laser Welding Machine Demo

This video showcases the JOYLASER Swing-Arm Mold Fiber Laser Welding Machine delivering high-precision results for mold surface repairs. Designed with a flexible swing-arm structure, the system allows 3D movement of the welding head, enabling accurate access to hard-to-reach areas on large or complex molds.

Equipped with a high-quality fiber laser source, it provides stable energy output, minimal thermal impact, and clean, smooth welds with no need for post-grinding. Ideal for repairing mold cracks, edges, pin holes, and worn cavities on materials like P20, H13, 718, and SKD61. A perfect tool for plastic, die-casting, and stamping mold maintenance.

Swing-Arm Mold Fiber Laser Welding Machine Technical Parameters

| Item | Specification |

|---|---|

| Laser Type | Fiber Laser |

| Laser Power | Optional: 150W / 200W / 300W |

| Wavelength | 1064nm |

| Max Welding Depth | ≤1.5mm (depending on material) |

| Control System | Digital Precision Control |

| Arm Length | Adjustable 600–800mm |

| Cooling Method | Industrial Water Cooling |

| Observation System | HD CCD Monitoring |

| Power Supply | AC220V / 50Hz |

Swing-Arm Mold Fiber Laser Welding Machine Customer Case

A German automotive parts supplier integrated JOYLASER’s Swing-Arm Mold Fiber Laser Welding Machine into its mold maintenance process. The result: 50% faster welding speed and a 30% reduction in mold rejections, significantly boosting production stability.

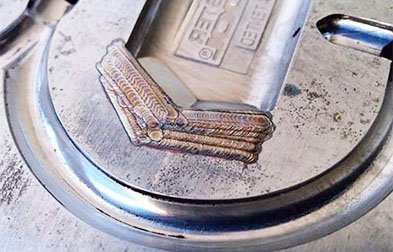

Swing-Arm Mold Fiber Laser Welding Machine Welding Example

Swing-Arm Mold Fiber Laser Welding Machine FAQ

Q1: What materials can this machine weld?

A1: It supports mold steel, stainless steel, carbon steel, and aluminum alloys.

Q2: Will the welding process deform the mold?

A2: The advanced thermal control minimizes the heat-affected zone, reducing deformation.

Q3: Is the swing arm customizable?

A3: Yes, we offer tailored arm lengths and reach based on customer needs.

Q4: Is the machine easy to operate?

A4: Yes, intuitive interface with 2-hour training. Remote and on-site training available.

Q5: What after-sales service is included?

A5: One-year warranty, lifetime tech support, and fast global spare parts delivery.

111-1024x458.png)