Mold Fiber Laser Welding Machine

The mold fiber laser welding machine is engineered for precision mold repair and fine metal welding. With high accuracy, minimal heat impact, and wide material compatibility, it’s ideal for automotive, injection molding, and medical device applications.

This is popup title

You don't need to waste your time and money anymore.

Description

Mold Fiber Laser Welding Machine Product Introduction

The mold fiber laser welding machine is an advanced solution specifically engineered for high-precision mold repair. It features a continuous or pulsed laser source with an adjustable spot size from 0.1mm to 3.0mm, delivering micron-level positioning accuracy. With a heat-affected zone smaller than 0.5mm, it effectively prevents deformation risks common in traditional welding processes.

This machine excels in repairing fine cracks in automotive stamping molds and worn sealing edges of injection molds. Post-weld polishing is often unnecessary, and etching can be applied directly, greatly improving repair efficiency. It supports a wide range of metals including copper, aluminum, and stainless steel, with a welding thickness range of 0.2mm to 6mm, making it ideal for dissimilar metal joining and thin-walled parts fabrication.

Equipped with an imported ceramic focusing cavity and dual-lamp system, the machine ensures stable energy delivery and strong, compact weld seams with low porosity. It meets the stringent cleanliness and precision standards required in the medical device industry. Whether you are a mold manufacturer, a medical device producer, or involved in automotive part repairs, this laser mold welding machine offers a reliable, precise, and efficient welding solution.

Mold Fiber Laser Welding Machine Core Advantages

Equipped with continuous or pulsed laser source for versatile welding needs

Laser enables spot adjustment from 0.1–3.0mm with micron-level precision; heat-affected zone < 0.5mm

Compatible with copper, aluminum, stainless steel, ideal for dissimilar metals and thin-wall components

Perfect for repairing mold cracks, sealing edges, and fine details in stamping molds

Clean, strong welds with low porosity; meets medical hygiene standards

Advanced water-cooling system ensures reliable long-term performance

low porosity. It meets the stringent cleanliness and precision standards required in the medical device industry. Whether you are a mold manufacturer, a medical device producer, or involved in automotive part repairs, this laser mold welding machine offers a reliable, precise, and efficient welding solution.

Mold Fiber Laser Welding Machine Technical Parameters

| Parameter | Value |

|---|---|

| Laser Power | 200W or 400W |

| Laser Wavelength | 1064nm |

| Laser Frequency | 1–20Hz |

| Condenser Type | Imported ceramic & double-lamp |

| Pulse Width | 0.1–10ms |

| Spot Size Adjustment | 0.3–2mm |

| Chiller Power | 1.5P or 3P |

| Rated Power | 8KW |

| Operating Voltage | 380V±5V 50Hz/40A or 110–220V±5V 50Hz/60A |

| Cooling Method | Water Cooling |

Mold Fiber Laser Welding Machine Demo

This video demonstrates the JOYLASER Mold Fiber Laser Welding Machine delivering precise, high-quality welds on mold components. Equipped with advanced fiber laser technology, it offers stable energy output and minimal heat-affected zones, ensuring clean, smooth, and deformation-free repairs.

The system is ideal for fixing cracks, worn edges, sunken areas, and surface pinholes on mold steels such as P20, 718, H13, and NAK80. Its fine beam control allows for accurate micro-welding, significantly reducing post-processing work. Widely used in injection molds, die-casting molds, and precision tooling maintenance, it is the perfect solution for high-efficiency mold repair operations.

Mold Fiber Laser Welding Machine Application Scene

Automotive stamping mold crack repair

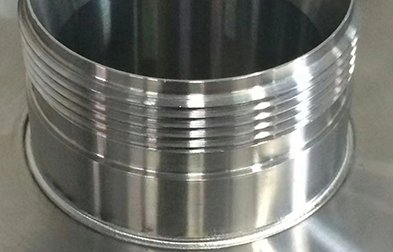

Injection mold sealing edge wear correction

Micro-welding of stainless steel medical components

Surface correction of precision mechanical parts

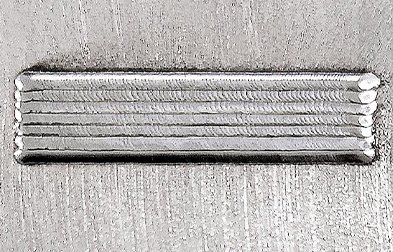

Mold Fiber Laser Welding Machine Customer Case

Case 1 – German Automotive Parts Manufacturer

Used for stamping mold crack welding; the weld allows for direct etching post-process without re-polishing, reducing labor time significantly.

Case 2 – U.S. Medical Device Company

Applied to stainless steel endoscope parts welding, achieving extremely low porosity to meet FDA-level cleanliness.

Mold Fiber Laser Welding Machine Example

Mold Fiber Laser Welding Machine (FAQ)

What thickness of metal does the mold fiber laser welding machine support?

A1: The mold fiber laser welding machinee supports metal welding from 0.2mm to 6mm, making it ideal for thin-walled and micro components.

Q2: Can the mold fiber laser welding machine weld dissimilar metals?

A2: Yes, the mold fiber laser welding machine can stably weld copper, aluminum, stainless steel, and other dissimilar metals.

Q3: Does the mold fiber laser welding machine cause mold deformation?

A3: No. The mold fiber laser welding machine uses pulse laser for precise heat control, with a heat-affected zone less than 0.5mm, effectively preventing deformation.

Q4: Is the mold fiber laser welding machine internationally certified?

A4: Yes, the mold fiber laser welding machine is CE and FDA certified, complying with global market standards.

Q5: What cooling system is required for the mold fiber laser welding machine?

A5: A 1.5P or 3P industrial water chiller is recommended to ensure stable and continuous performance of the laser mold welding machine.

111-1024x458.png)