Handheld Laser Welding Machine

The handheld laser welding machine is a compact, portable, and high-efficiency solution for precision metal welding. Ideal for stainless steel, aluminum, carbon steel, and more, it features deep weld penetration, minimal distortion, and smooth seams with no need for post-processing. With plug-and-play operation and fast setup, it’s perfect for workshops, factories, and on-site welding tasks.

This is popup title

You don't need to waste your time and money anymore.

Description

Handheld Laser Welding Machine Product Introduction

The handheld laser welding machine is a highly efficient, flexible, and user-friendly welding solution. Compared to traditional methods, it features a handheld welding gun that replaces the fixed optical path, significantly enhancing welding flexibility and enabling long-distance or irregular-shaped component welding, overcoming workspace limitations.

Equipped with a red light positioning system, it ensures accurate alignment of the welding head for precise and aesthetically pleasing results. With high-energy laser output, it achieves deep penetration welding with strong joints and minimal heat distortion.

The weld seams are neat and smooth, eliminating the need for secondary polishing or grinding, which greatly improves post-weld efficiency.

Thanks to its intuitive operation interface, even non-certified personnel can easily operate the machine, helping reduce labor and training costs. It is especially suitable for industries such as hardware, kitchenware, stainless steel doors and windows, elevators, and signage.

Handheld Laser Welding Machine Core Advantages

The handheld laser welding machine’s welding gun replaces traditional fixed optics, enabling long-distance and complex-angle welding with greater flexibility.

Red light alignment system ensures precise positioning of the weld, reducing manual errors.

Deep penetration and strong welds make it ideal for structural components and demanding applications.

Minimal heat-affected zone helps reduce deformation, spatter, and common welding defects.

Clean and smooth seams reduce or eliminate the need for post-weld grinding or polishing.

User-friendly operation with no welding license required — most users can begin after just one hour of training.

Compatible with a wide range of metals, including stainless steel, aluminum, copper, carbon steel, and galvanized sheets.

Handheld Laser Welding Machine Demo

This video features the JOYLASER Handheld Laser Welding Machine performing efficient, high-quality welds on metal workpieces of various shapes and sizes. Designed for flexibility and ease of use, the machine combines a powerful fiber laser source with a lightweight ergonomic welding gun. It supports continuous or pulse welding modes and adapts to materials like stainless steel, carbon steel, aluminum, and galvanized sheet.

The system produces deep, narrow, and clean weld seams with minimal heat input and no filler wire. It is widely used in sheet metal fabrication, automotive repair, kitchenware production, and metal structures—ideal for small to medium manufacturers seeking productivity and precision in one compact solution.

Handheld Laser Welding Machine Technical Parameters

| Item | Value |

|---|---|

| Laser Type | Fiber Laser |

| Power Options | 1500W / 2000W / 3000W |

| Welding Depth | 0.5mm – 5mm (varies by material) |

| Welding Speed | 0–120 mm/s |

| Laser Wavelength | 1070nm |

| Control System | Touchscreen + PLC |

| Cooling Method | Air Cooling or Water Cooling (optional) |

| Voltage | 220V / 50–60Hz, 380V / 50–60Hz |

| Working Mode | Continuous / Spot Welding |

| Laser Frequency | 1000–3000 KHz |

| Fiber Length | Standard 10 meters, customizable up to 15 meters |

| Weld Seam Width | 0.2mm – 5mm |

| Supported Metals | Stainless Steel, Aluminum, Copper, Carbon Steel, Galvanized Sheet, etc. |

Handheld Laser Welding Machine Application Areas

The handheld laser welding machine is widely used for welding various metal products, including:

Kitchen equipment (range hoods, sinks, countertops)

Advertising signs and letters

Battery housings and metal parts

Door and window frames, railings

Appliance casings

Auto parts (frames, exhaust pipes)

Customer Cases

Case 1: Kitchenware Manufacturer in China

Used 1500W handheld laser welder to replace TIG welding for stainless steel sinks. Welding speed doubled, and post-processing reduced by 70%, saving over 30% in labor costs monthly.

Case 2: E-bike Workshop in Germany

Used 2000W model to weld aluminum frames. Results showed strong, splash-free welds with smooth surfaces. Easy to operate and maintain.

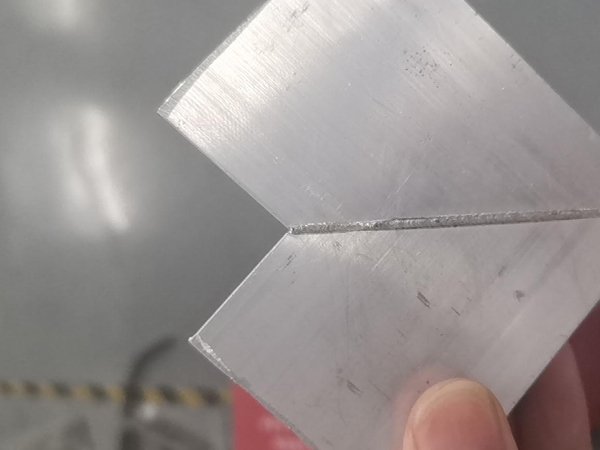

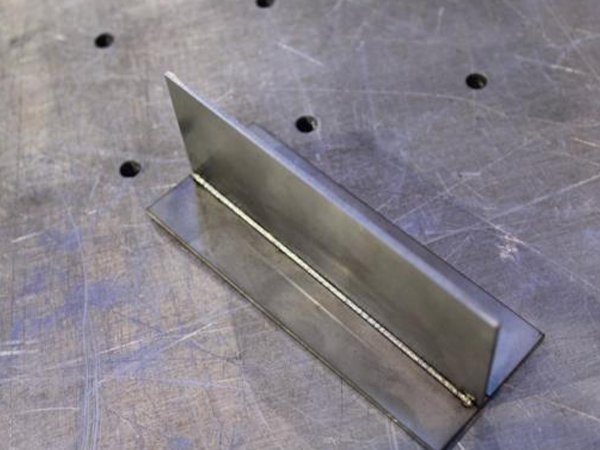

Handheld Laser Welding Welding Example

Handheld Laser Welding Machine Frequently Asked Questions (FAQ)

Q1: Is the handheld laser welding machine suitable for beginners?

A1: Yes, the handheld laser welding machine features a user-friendly interface and intuitive controls. Most operators can be trained and start working within one hour.

Q2: What materials can the handheld laser welding machine weld?

A2: The handheld laser welding machine is compatible with stainless steel, aluminum, carbon steel, galvanized sheets, copper, and more.

Q3: Will the handheld laser welding machine cause welding defects like burn-through or weld bumps?

A3: No. When parameters are properly set and red light alignment is used, the handheld laser welding machine delivers clean welds without defects.

Q4: Is post-weld grinding necessary when using the handheld laser welding machine?

A4: In most cases, weld seams produced by the handheld laser welding machine are neat and smooth, eliminating the need for secondary polishing.

Q5: What is the required input voltage for the handheld laser welding machine?

A5: The handheld laser welding machine supports both 220V and 380V, 50–60Hz, to accommodate different industrial environments.

Q6: What is the welding depth range of the handheld laser welding machine?

A6: The welding depth ranges from 0.5mm to 5mm, depending on the material and the laser power used in the handheld laser welding machine.

Q7: Can the handheld laser welding machine support long-distance welding?

A7: Yes. The handheld laser welding machine comes with a standard 10-meter fiber cable and can be optionally upgraded to 15 meters for extended reach.

111-1024x458.png)