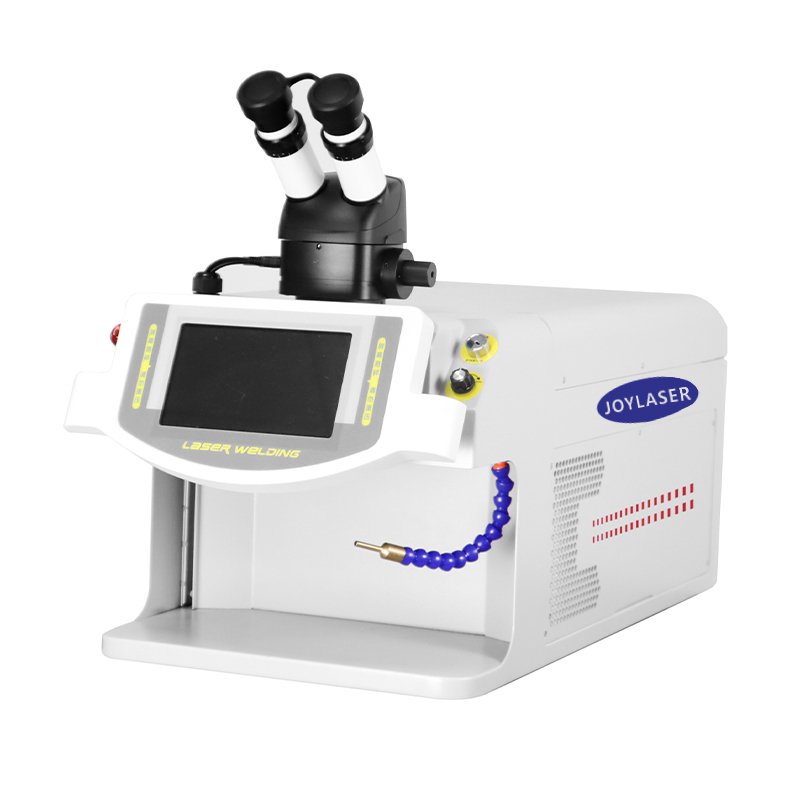

Mini Jewelry Laser Welding Machine

This mini jewelry laser welding machine is designed for precise welding and repair of gold and silver jewelry. Its compact size and easy operation make it ideal for various jewelry studios and repair shops.

This is popup title

You don't need to waste your time and money anymore.

Description

Mini Jewelry Laser Welding Machine Product Introduction

The Mini Jewelry Laser Welding Machine is a compact, high-precision welding device specially designed for the jewelry industry. Utilizing pulsed YAG laser technology, it enables high-quality, non-contact welding on precious metals such as gold, silver, platinum, and stainless steel. With its small footprint and compact design, it is ideal for space-constrained jewelry studios, showrooms, or mobile repair services. Equipped with a high-precision welding spot adjustment system, it ensures clean, firm welds, making it particularly suitable for micro-welding tasks such as ring repair, chain welding, and prong restoration.

The mini jewelry laser welding machine supports both touchscreen and foot pedal control, offering stable energy output, uniform spot size, and aesthetically pleasing weld seams. The built-in cooling system ensures long-term stable operation. With a compact structure, easy maintenance, and minimal consumables, this machine is the perfect choice for jewelers, repair technicians, and small workshop startups.

Mini Jewelry Laser Welding Machine Product Core Advantages

Compact size for easy portability

High-precision welding suitable for small components

User-friendly operation for various users

Compatible with multiple metals like gold, silver, platinum

Built-in cooling system ensures stable performance

Mini Jewelry Laser Welding Machine Application Scenarios

Precise welding and repair of gold and silver jewelry

Daily welding tasks in jewelry studios

Quick repair services in jewelry repair shops

Teaching equipment in training institutions

Mini Jewelry Laser Welding Machine Demo

In this demo, the JOYLASER mini jewelry laser welding machine shows excellent performance in fine jewelry repair. Compact and user-friendly, it uses high-energy pulse laser technology to seamlessly weld or fix rings, earrings, chains, and other fine accessories.

With minimal heat impact, the welds are clean and smooth—no dark edges or polishing required. Ideal for gold, silver, platinum, titanium, and stainless steel, it’s perfect for jewelry stores, workshops, and custom studios—your reliable solution for high-end micro welding.

Mini Jewelry Laser Welding Machine Technical Specifications

| Parameter | Specification |

|---|---|

| Laser Type | Pulsed YAG Laser |

| Laser Power | 60W / 100W / 150W (optional) |

| Wavelength | 1064nm |

| Spot Diameter | 0.2mm – 2.0mm |

| Pulse Width | 0.1ms – 20ms |

| Pulse Frequency | 1Hz – 50Hz |

| Observation System | Built-in Microscope or HD CCD System |

| Control Mode | Touchscreen + Foot Pedal |

| Cooling Method | Built-in Water Cooling |

| Power Supply | AC220V±10% / 50Hz |

| Dimensions | 510 × 290 × 280mm |

| Net Weight | 28kg |

Mini Jewelry Laser Welding Machine Customer Cases

Jewelry Repair Studio in Paris, France: After adopting the mini jewelry laser welding machine, the studio significantly improved repair efficiency for rings and chains, reducing processing time by 30% per item and increasing customer satisfaction.

Jewelry Repair Studio in Paris, France: After adopting the mini jewelry laser welding machine, the studio significantly improved repair efficiency for rings and chains, reducing processing time by 30% per item and increasing customer satisfaction.

Jewelry Souvenir Shop in Chiang Mai, Thailand: Ideal for on-site repairs and demonstrations. The compact design makes it a top choice for tourist jewelry customization services.

Mini Jewelry Laser Welding Machine Welding Example

Mini Jewelry Laser Welding Machine FAQ

Q1: What materials can the mini jewelry laser welding machine weld?

A1: The mini jewelry laser welding machine is suitable for welding various precious metals like gold, silver, platinum, stainless steel, and titanium alloys. It is ideal for micro-welding tasks such as rings, chains, and pendants.

Q2: Can beginners operate this mini jewelry laser welder easily?

A2: Yes, the mini jewelry laser welder is equipped with a touchscreen and foot pedal for intuitive operation. It’s perfect for beginners, jewelry repair technicians, or small studios.

Q3: Will the mini jewelry laser welding machine overheat during long-term use?

A3: The machine features an efficient built-in water cooling system, allowing the mini jewelry laser welding machine to operate continuously without overheating.

Q4: Is it difficult to maintain this jewelry laser welding machine?

A4: Daily maintenance is easy—just replace the cooling water regularly and clean the protective lens. The mini jewelry laser welder is compact and uses durable consumables, making upkeep affordable.

Q5: Does this mini laser welding machine support customization or CCD integration?

A5: Yes, customization is available. You can integrate CCD monitoring, a microscope, or an expanded working platform to match various jewelry welding needs.

Q6: What applications is the mini jewelry laser welding machine suitable for?

A6: It’s ideal for jewelry repair shops, small studios, brand showrooms, and mobile service units where space efficiency and precision are required.

111-1024x458.png)