MOPA Galvo Laser Welding Machine

The MOPA Galvo Laser Welding Machine features adjustable pulse width and high beam quality, enabling stable and precise welding on high-reflective materials such as copper and aluminum. Ideal for electronics, battery manufacturing, and precision components.

This is popup title

You don't need to waste your time and money anymore.

Description

MOPA Galvo Laser Welding Machine Product Information

Featuring high beam quality and flexible pulse width control, the MOPA Galvo Laser Welding Machine excels at welding high-reflective metals such as copper and aluminum. Powered by a MOPA laser source, it offers flexible pulse width (2ns–500ns) and high-frequency modulation (1kHz–2000kHz), enabling users to fine-tune energy delivery for various materials.

Its advanced galvo scanning system enables ultra-fast welding up to 0.7m/s, while the superior beam quality and spot size down to 0.2mm ensure exceptional accuracy. Air cooling design makes it compact and maintenance-friendly.

The MOPA Galvo Laser Welding Machinein welding difficult materials such as copper, aluminum, and dissimilar metals with minimal thermal distortion, making it ideal for industries like lithium battery production, 3C electronics, medical devices, and aerospace.

MOPA Galvo Laser Welding Machine Key Advantages

Adjustable pulse width (2ns–500ns) for optimized energy control

Supports high-frequency welding up to 2000kHz

Excellent performance on high-reflective metals (Cu/Al)

Ultra-fine welding spot: as small as 0.2mm

High-speed galvo scanning (≤0.7m/s)

Compact air-cooled design, easy to maintain

Suitable for micro-welding and precision electronics

MOPA Galvo Laser Welding Machine Demo

This video showcases the JOYLASER MOPA Galvo Laser Welding Machine in action, delivering high-precision welding for fine metal parts. Equipped with a MOPA pulsed fiber laser and high-speed galvanometer scanning system, it enables non-contact, programmable welding paths ideal for thin-walled components, microstructures, and delicate areas.

The MOPA laser allows flexible control of pulse duration and heat input, resulting in smooth, detailed weld seams with minimal heat-affected zones. This reduces deformation and ensures excellent results on heat-sensitive materials. The galvo system provides fast, stable beam movement without repositioning the workpiece, making it especially suitable for electronics, battery tabs, and precision hardware. Combining accuracy with efficiency, it’s the perfect solution for high-end, small-scale industrial welding needs.

MOPA Galvo Laser Welding Machine Technical Parameters

| Technical Parameter | Specification |

|---|---|

| Laser Power | 50-100W |

| Laser Wavelength | 1064nm |

| Pulse Width Range | 2ns – 500ns |

| Laser Frequency | 1kHz – 2000kHz |

| Voltage | 220V |

| Welding Speed | ≤0.7m/s |

| Laser Type | MOPA |

| Cooling Method | Air Cooling |

| Welding Spot Diameter | As small as 0.2mm |

MOPA Galvo Laser Welding Machine Application Scenarios

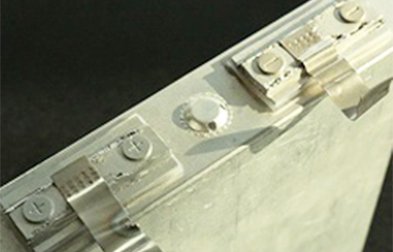

Power battery busbar welding (copper, aluminum)

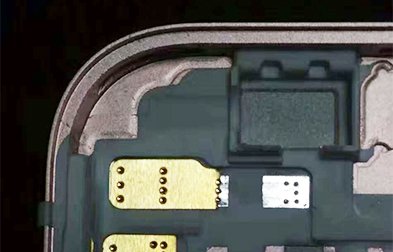

3C electronic components (mid-frame shrapnel, antenna shrapnel)

Smart wearables and camera module welding

Thin-walled stainless steel parts and precision micro motors

Medical device components

MOPA Galvo Laser Welding Machine Customer References

Case 1: Chinese Power Battery Manufacturer

Case 1: Chinese Power Battery ManufacturerUsed for welding copper-aluminum battery busbars with excellent strength and uniformity, resulting in over 30% increase in production line efficiency. The system runs reliably and supports 24/7 operations.

Case 2: European Medical Device Company

Achieved precise micro-welding for medical sensors with minimal thermal impact, increasing yield rate by 20%, and passed rigorous welding quality validation for medical devices.

Case 3: Southeast Asia 3C Electronics Manufacturer

Used for welding mid-frame shrapnel in 3C electronics, replacing traditional methods. Resulted in 25% higher yield and over 40% reduction in labor costs.

Welding Samples of MOPA Galvo Laser Welding Machine

MOPA Galvo Laser Welding Machine (FAQ)

Q1: What types of metals can MOPA Galvo Laser Welding Machine weld?

A: MOPA Galvo Laser Welding Machine is suitable for copper, aluminum, stainless steel, nickel, and their combinations.

Q2: Is MOPA Galvo Laser Welding Machine suitable for continuous production lines?

A: Yes, MOPA Galvo Laser Welding Machine supports integration into automated lines and robotic arms.

Q3: How does MOPA Galvo Laser Welding Machine handle high-reflective materials like aluminum or copper?

A: MOPA Galvo Laser Welding Machine uses a MOPA laser source that provides stable energy control with adjustable pulse width to ensure smooth welding without spatter or damage.

Q4: What maintenance is required for MOPA Galvo Laser Welding Machine?

A: MOPA Galvo Laser Welding Machine requires regular cleaning of optical components, checking cooling system levels, and keeping the software updated to ensure optimal performance.

Q5: Can MOPA Galvo Laser Welding Machine weld dissimilar metals?

A: Yes, MOPA Galvo Laser Welding Machine is optimized for dissimilar metal welding such as copper to aluminum or nickel to steel.

111-1024x458.png)