Multi-Axis Platform Galvo Laser Welding Machine

The Multi-Axis Platform Galvo Laser Welding Machine integrates high-speed galvo scanning with multi-axis platform motion, enabling precise welding of complex components, suitable for automated production in battery, electronics, medical, and other industries.

This is popup title

You don't need to waste your time and money anymore.

Description

Multi-axis Galvo Platform Laser Welding Machine Machine Product Introduction

The Multi-Axis Platform Galvo Laser Welding Machine combines high-speed galvo scanning technology with a multi-axis motion platform to deliver precise and efficient welding of complex components. Equipped with advanced laser sources and intelligent control systems, it ensures stable weld quality and aesthetically pleasing seams without the need for secondary processing. Widely used in battery manufacturing, electronic components, medical devices, and precision hardware industries, it meets diverse welding requirements. The machine supports multiple welding modes, including spot welding, seam welding, and seal welding, and offers strong customization options such as adjustable laser power, platform size, and fixture design, helping businesses enhance production efficiency and product competitiveness.

Multi-axis Galvo Platform Laser Welding Machine Key Advantages

High Speed and Precision: Galvo scanning combined with a multi-axis platform achieves welding accuracy of ±0.01mm.

Multiple Welding Modes: Supports spot welding, seam welding, seal welding, and other welding methods to meet various process requirements.

Flexible Customization: Laser power, platform size, fixtures, and more can be customized according to customer needs to suit diverse production.

Intelligent Control System: Equipped with an industrial PC and professional welding software, supporting graphical programming and multi-process switching.

Automation Integration: Compatible with automated production lines to improve efficiency and welding consistency.

Multi-axis Galvo Platform Laser Welding Machine Application Scenarios

Battery Welding: High-precision welding of battery tabs, housings, and other components.

Electronic Components Welding: Precise welding of small parts such as circuit boards and connectors.

Medical Device Manufacturing: Welding of medical instruments made from stainless steel, titanium alloys, and other materials.

Precision Hardware Processing: High-quality welding for products like phone housings and metal jewelry.

Automotive Parts Welding: Welding of automotive electronic components such as sensors and connectors.

Multi-Axis Galvo Laser Welding Machine – Live Welding Demo

This video shows the JOYLASER multi-axis platform galvo laser welding machine precisely welding EV battery housings and cell connections. Combining high-speed galvo scanning with X/Y/Z multi-axis motion, it efficiently handles complex welding paths, ideal for dense, compact, and heat-sensitive battery welds.

The system minimizes heat impact to prevent distortion and spatter, producing smooth, consistent welds on aluminum, nickel, and copper materials. Features like auto-alignment and programmable paths greatly improve automation and weld consistency, making it an excellent laser welding solution for modern battery manufacturing.

Multi-axis Galvo Platform Laser Welding Machine Technical Specifications

| Item | Specification |

|---|---|

| Laser Type | Continuous Wave (CW) Fiber Laser or Quasi-Continuous Wave (QCW) Fiber Laser |

| Laser Power | 1000W / 1500W / 2000W / 3000W (Optional) |

| Laser Wavelength | 1080 ±10 nm |

| Welding Mode | Galvo Scanning + Multi-Axis Platform Motion |

| Welding Accuracy | ±0.01 mm |

| Platform Motion | XYZ Axis Servo Motor Control, Optional Rotary Axis |

| Control System | Industrial PC + Professional Welding Software |

| Cooling Method | Water Cooling |

| Optional Features | CCD Monitoring, Vision Positioning, Rotary Table, Auto Loading & Unloading System |

| User Interface | Graphical Human-Machine Interface (HMI) |

| Input Power Supply | AC220V ±10%, 50/60Hz |

| Machine Dimensions | Customized Based on Configuration |

| Safety Features | Laser Safety Enclosure, Emergency Stop Button, Safety Interlock System |

Multi-axis Galvo Platform Laser Welding Machine Customer Cases

Leading Chinese EV Battery Manufacturer

A top-tier power battery enterprise in China integrated the multi-axis platform galvo laser welding machine into its battery module production line. The system enabled fully automated welding of battery tabs and casings, resulting in a 30% increase in daily output and a 25% reduction in weld defect rates, significantly improving mass production consistency and reliability.

Well-Known Korean Electronics Brand (Smartphone Division)

A renowned smartphone OEM manufacturer adopted the system for precision welding of aluminum-magnesium alloy phone housings. With ±0.01mm welding accuracy and aesthetically clean weld seams that require no post-processing, the solution helped the client reduce assembly takt time by 20% while maintaining high-end product appearance standards.

German Medical Device Manufacturer

A specialized German medical equipment company used the system to weld stainless steel and titanium surgical instruments, where low heat-affected zones and high cleanliness were essential. The galvo laser welding technology delivered zero thermal damage and contamination-free welds, passing ISO 13485 medical welding certification and supporting flexible small-batch production needs.

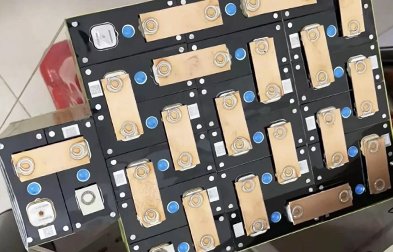

Multi-Axis Platform Galvo Laser Welding Machine Welding Example

Multi-Axis Platform Galvo Laser Welding Machine FAQ

Q1 : What welding modes does the multi-axis platform galvo laser welding machine support?

A1 : It supports various laser welding modes, including spot welding, seam welding, and seal welding, suitable for battery welding, electronics, and precision applications.

Q2 : Can the multi-axis laser welding system be integrated into an automated production line?

A2 : Yes, this laser welding machine can be seamlessly integrated into automated production lines, enabling high-speed welding and consistency.

Q3 : Do you offer customization for laser welding equipment?

A3 : Yes, we provide tailored solutions for laser power, platform dimensions, and fixture designs, supporting various industrial welding applications.

Q4 : What is the maintenance cycle for this multi-axis laser welding system?

A4 : Routine maintenance is recommended every 6 months. The precision laser welder features modular design for easy upkeep and stable long-term performance.

111-1024x458.png)