Description

Joylaser Portable Handheld Laser Welding Machine Product Introduction

The portable handheld laser welding machine combines portability, precision, and efficiency into one advanced laser welding device. Utilizing cutting-edge fiber laser technology, it delivers a high-energy-density laser beam that rapidly melts and cools the weld area, minimizing heat-affected zones and preventing distortion of the workpiece. Designed ergonomically, it offers flexible operation suitable for handheld tasks in various complex working conditions.

This laser welder supports welding of multiple metal materials such as stainless steel, aluminum alloy, copper, and titanium alloy. It is widely used in electronics component repair, automotive parts welding, jewelry manufacturing, and hardware tool restoration. Users can adjust laser power and welding speed to achieve different welding depths and strengths according to their specific needs.

Additionally, the handheld laser welding machine features an intelligent control system with versatile welding parameter settings to ensure stable and consistent welds every time. Equipped with air or water cooling systems, it guarantees long-term reliable operation. Its portable design not only facilitates on-site repairs but also significantly improves production efficiency and welding quality, making it an ideal solution for modern manufacturing and maintenance industries.

Portable Handheld Laser Welding Machine Core Advantages

Portable and Lightweight: Ergonomically designed for easy handheld operation and convenient transportation.

High Precision and Efficiency: Focused laser beam enables precise welding of micro weld spots with minimal heat-affected zones.

Multi-Material Compatibility: Suitable for welding stainless steel, aluminum alloy, copper, titanium alloy, and more.

Minimal Thermal Deformation: Reduces distortion and damage, maintaining high weld strength and structural integrity.

Intelligent Control System: Adjustable welding parameters to meet diverse application requirements and ensure consistent performance.

Durable Cooling System: Equipped with efficient air or water cooling to support long-duration and stable welding processes.

User-Friendly Operation: Simple interface and ergonomic design reduce operator fatigue and improve productivity.

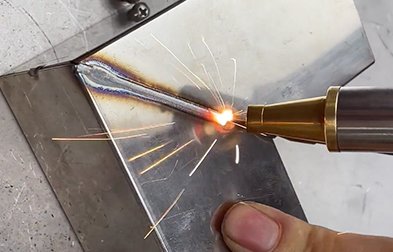

Portable Handheld Laser Welding Machine Welding Demo

In this demo, the portable handheld laser welding machine stands out with its compact design and powerful performance. Lightweight and easy to carry, it’s ideal for on-site operations and small-to-medium workshops. With precise laser focus, it welds stainless steel, carbon steel, and aluminum with ease—ensuring deep penetration, minimal heat distortion, and beautiful, strong seams. Ready to use instantly and built for continuous work, it’s the perfect welding upgrade for furniture, doors and windows, kitchenware, electrical enclosures, and more!

Portable Handheld Laser Welding Machine Technical Specifications

| Parameter | Specification |

|---|---|

| Laser Type | Fiber Laser |

| Laser Power | 1000W / 1500W / 2000W / 3000W (Optional) |

| Wavelength | 1064 nm |

| Welding Depth | 0.1 – 2 mm |

| Operation Mode | Handheld |

| Cooling Method | Air Cooling / Water Cooling |

| Welding Speed | Adjustable |

Portable Handheld Laser Welding Machine Technical Specifications

Sheet Metal Processing: Ideal for precision welding of stainless steel and carbon steel components.

Kitchenware & Home Appliances: Perfect for welding sinks, ovens, water dispensers, and other metal household hardware.

Advertising Industry: Suitable for assembling metal letters, signage frames, and display structures.

Electronics Manufacturing: Enables precise welding of enclosures, connectors, and metal brackets.

Automotive Industry: Widely used for welding battery components, exhaust systems, and interior metal fittings.

Furniture and Metal Frames: Applied in welding table frames, chairs, shelves, and decorative metal structures.

Portable Handheld Laser Welding Machine Customer Cases

Germany – Sheet Metal Fabrication Workshop:

A medium-sized metal processing company in Stuttgart integrated our 1500W handheld laser welding machine to replace traditional TIG welding. Result: welding speed increased by 3×, labor cost reduced by 40%, and customer return rate dropped significantly.USA – Kitchen Equipment Manufacturer:

A commercial kitchen appliance brand based in Chicago adopted the 2000W model for stainless steel sink and cabinet welding. The smooth weld seams and low thermal deformation improved product aesthetics and structural reliability.Mexico – Advertising Sign Maker:

A signage production firm in Monterrey applied our handheld laser welder to produce aluminum lightbox frames and metal characters. It helped them shorten production time and reduce the need for post-polishing.Thailand – Automotive Components Supplier:

A supplier of interior automotive brackets and exhaust covers upgraded to JOYLASER’s 1000W unit, optimizing the precision of thin sheet welding while improving consistency across production batches.

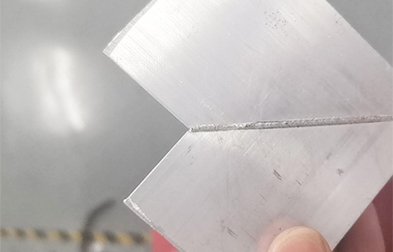

Portable Handheld Laser Welding Machine Welding Example

Portable Handheld Laser Welding Machine FAQ

Q1: What metals are suitable for the portable handheld laser welding machine?

A1: The device is compatible with stainless steel, aluminum alloy, copper, titanium alloy, and various other metals to meet diverse welding needs.

Q2: Does the machine require special operator training?

A2: The operation is straightforward, but basic training is recommended to ensure weld quality and safety.

Q3: Does the device overheat during welding?

A3: It features air or water cooling systems to prevent overheating and ensure stable long-term operation.

Q4: Can welding parameters be customized?

A4: Yes, users can freely adjust power, speed, and other parameters according to different welding requirements.

111-1024x458.png)