Description

QCW Galvo Platform Laser Welding Machine Product Introduction

The QCW Galvo Platform Laser Welding Machine combines a pulsed QCW fiber laser source with a high-speed galvanometer scanning system to perform precise spot, seam, and trajectory welding. It’s ideal for micro-welding applications such as battery tab welding, medical instruments, precision sensors, and thin metal foils.

This system supports multi-axis movement, optional vision positioning, and various I/O interfaces for automation integration. The laser delivers stable output and low heat input, minimizing deformation and achieving exceptional weld quality for delicate components.

QCW Galvo Platform Laser Welding Machine Key Advantages

High-frequency galvo scanning enables fast and precise welding

QCW pulsed laser source ideal for heat-sensitive materials

Supports multi-axis platform for complex path welding

Optional visual positioning system for high welding accuracy

Minimal heat-affected zone, no post-processing required

Easily integrated with automated production lines

Stable laser energy output ensures consistent weld quality

QCW Galvo Platform Laser Welding Machine Application Scenarios

Battery Tab Welding

Ideal for welding lithium battery tabs and bus bars, especially where minimal heat-affected zones and clean welds are critical.Medical Device Manufacturing

Used for joining titanium micro-tubes, stainless steel catheters, and sensor housings with biocompatibility and FDA-compliant quality.Precision Electronics and Connectors

Suitable for fine welding of electronic components, pins, micro-connectors, and RF shielding enclosures.Jewelry and Watch Repair

Enables clean, precise spot welding for gold, silver, platinum, and stainless-steel watch components.Sensor and Instrument Assembly

Ideal for hermetically sealing precision sensors, optical devices, and measuring instruments in aerospace and laboratory environments.Automotive Microcomponents

Suitable for welding fine parts such as fuel injector nozzles, pressure sensors, and electrical connectors.Communication Devices

Applied in welding metal shells, fiber-optic parts, and shielding covers for communication modules and 5G components.Aerospace and Defense

Perfect for microstructure welding in navigation systems, satellite parts, and lightweight high-strength components.

QCW Galvo Platform Laser Welding Machine Demo

In this video, the JOYLASER QCW galvo platform laser welder precisely handles micro metal welds. Using a QCW laser source with galvo scanning and XYZ motion, it suits mold repair, 3C electronics, and precision parts.

With minimal heat impact and smooth, clean welds, it supports stainless steel, copper, aluminum, and more. It enables programmable paths and flexible integration—ideal for precision manufacturing.

QCW Galvo Platform Laser Welding Machine Technical Specifications

| Item | Specification |

|---|---|

| Laser Type | QCW Pulsed Fiber Laser |

| Laser Power | Optional 75W / 150W / 300W |

| Laser Wavelength | 1064nm |

| Welding Mode | Galvo Scanning + Multi-axis Platform Motion |

| Welding Accuracy | ±0.01mm |

| Control System | Industrial PC + Professional Welding Software |

| Cooling Method | Water Cooling |

| Platform Motion | XYZ Axis with Servo Motor Control |

| Optional Features | CCD Monitoring, Vision Positioning, Rotary Table |

| User Interface | Graphical HMI Interface |

| Input Power Supply | AC220V ±10%, 50/60Hz |

| Machine Dimensions | Customized Based on Configuration |

| Safety Features | Laser Safety Enclosure, Emergency Stop, Interlock |

QCW Galvo Platform Laser Welding Machine Customer Cases

Japanese Battery Manufacturer

Adopted the 300W QCW galvo platform laser welding machine for battery tab welding. Welding pass rate increased from 92.8% to 99.2%, with reduced spatter and higher throughput.

US Medical Device Company

Used for welding stainless steel catheters and titanium micro-tubes. Welds are burr-free and ultra-clean, meeting FDA standards for traceability and contamination-free processing.

German Electronic Components Manufacturer

Integrated the machine with multi-axis and visual systems for welding micro sensor housings. Enabled fast product switching and improved welding uniformity on automation lines.

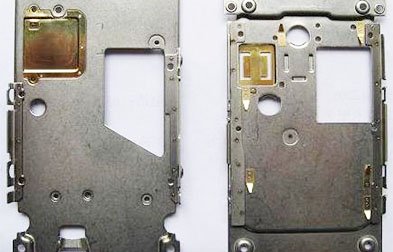

QCW Galvo Platform Laser Welding Machine Welding Example

QCW Galvo Platform Laser Welding Machine FAQ

Q1: What materials can this QCW galvo platform laser welder process?

A1: It can weld stainless steel, aluminum, titanium, nickel, copper, and gold.

Q2: Can this machine be integrated into an automated production line?

A2: Yes, it supports I/O ports, Modbus communication, and PLC integration.

Q3: Is it suitable for heat-sensitive micro-welding applications?

A3: Absolutely, thanks to its stable QCW output and minimal heat-affected zone.

Q4: What power options are available?

A4: 75W, 150W, and 300W are available to meet varying thickness and speed needs.

111-1024x458.png)