Description

Joylaser QCW Mold Laser Welding Machine Product Introduction

The QCW Mold Laser Welding Machine is a precision-engineered system designed specifically for mold repair and micro-precision welding. Equipped with a high peak-power QCW fiber laser source and a stable motion platform, it ensures accurate restoration of cracks, edges, and worn areas on molds. It is compatible with various metals such as steel, aluminum, copper, and titanium, and is especially ideal for high-reflective materials and applications requiring low thermal input. The system features a high-resolution CCD monitoring system and supports multi-axis linkage for intuitive operation, stable welding, and aesthetically clean seams. It is widely used in micro-repair and localized re-welding of injection molds, die-casting molds, and stamping molds—effectively extending mold life and reducing replacement costs.

Joylaser QCW Mold Laser Welding Machine Core Advantages

High-Energy Precision Control: Equipped with a QCW fiber laser supporting both continuous and pulsed modes, ideal for repairing cracks and corners of molds with minimal heat-affected zone and distortion.

Ultra-Fine Welding Quality: The highly focused laser beam ensures no spatter, no pores, and smooth weld seams, suitable for high-precision and aesthetic mold repairs.

Supports Multiple Metal Materials: Capable of welding mold steel, tungsten steel, stainless steel, chromium steel, and aluminum alloys—especially suitable for hard and high-conductivity mold materials.

Low Heat Input, Prolonged Mold Lifespan: The pulsed mode enables precise energy control, effectively avoiding mold annealing or burn-in, extending the mold’s service life.

Reliable Industrial Design: Integrated with a compact, dustproof, anti-vibration, and interference-resistant structure, supporting 24/7 stable industrial use.

QCW Mold Laser Welding Machine Application Scenarios

Injection mold repair

Stamping mold patch welding

Precision micro-part welding

Hardware re-welding

Microelectronic component welding

Medical mold micro-welding

QCW Mold Laser Welding Machine Welding Demo

In this demo, the JOYLASER QCW mold laser welding machine efficiently repairs mold cracks, dents, corner collapses, and fine surface defects. Featuring QCW fiber laser technology, it combines pulsed precision with continuous stability, delivering focused welds with minimal heat impact and no deformation.

Ideal for high-hardness mold steels such as P20, 718, H13, and NAK80, it’s widely used for repairing injection molds, die-casting molds, and stamping dies. The resulting welds are smooth, spatter-free, and require no post-polishing—greatly reducing repair time and improving efficiency.

QCW Mold Laser Welding Machine Technical Specifications

| Item | Specification |

|---|---|

| Laser Type | QCW Fiber Laser |

| Laser Power | 75W / 150W / 300W (Optional) |

| Wavelength | 1064nm |

| Working Mode | Continuous / Quasi-CW / Pulse switchable |

| Max Pulse Energy | 15J (with 300W laser) |

| Pulse Width Range | 0.1ms – 50ms |

| Pulse Frequency Range | 1Hz – 500Hz |

| Fiber Delivery | QBH Interface / Fiber Transmission |

| Focal Length Options | 100mm / 150mm / 200mm |

| Focus Adjustment | Electric / Manual (Optional) |

| Control System | Touch Screen + Foot Pedal |

| Positioning System | CCD Camera / Red Light Pointer (Optional) |

| Cooling Method | Integrated Water Cooling System |

| Input Power Supply | AC220V ±10%, 50/60Hz |

| Working Temperature | 10℃ – 35℃ |

| Machine Dimensions | 900mm × 600mm × 1300mm (for reference) |

| Net Weight | Approx. 180kg (depends on configuration) |

QCW Mold Laser Welding Machine Customer Cases

Germany – Precision Mold Repair Factory

A high-end German mold repair company replaced traditional TIG welding with our QCW fiber laser mold welding machine. The result: micro-crack defects were significantly reduced, and the average repair cycle time decreased by 30%, boosting overall repair efficiency and precision.

South Korea – Electronics Connector Manufacturer

A Korean customer specializing in precision electronic connectors applied the QCW laser welding machine to repair micro-mold cavities. The QCW pulse mode allowed them to achieve burr-free, smooth welding seams, and reduced mold scrap rate from 8% to 1.5%.

USA – Aerospace Component Supplier

A U.S.-based aerospace parts supplier used our QCW mold welding machine to repair high-reflective titanium alloy tooling molds. The machine provided highly stable and precise energy control, improving repair strength while avoiding thermal deformation.

Thailand – Automotive Molding Factory

One of Thailand’s top automotive mold makers used the QCW fiber laser welding machine for small-area insert repairs and deep cavity reinforcement. The customer reported a 40% improvement in rework precision compared to conventional arc welding.

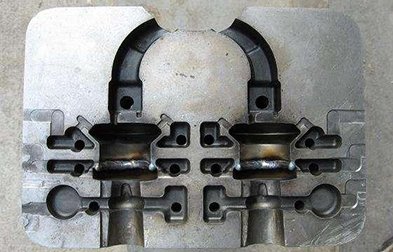

QCW Mold Laser Welding Machine Welding Example

QCW Mold Laser Welding Machine FAQ

Q1: What materials can the QCW mold laser welding machine weld?

A1: It can weld mold steel, stainless steel, aluminum alloy, copper, titanium, and more—especially suitable for reflective and thin materials.

Q2: Can it achieve high-precision micro welding?

A2: Yes, with the QCW pulse mode and precision stage, it supports micron-level welding accuracy.

Q3: Is shielding gas welding supported?

A3: Yes, it supports argon and nitrogen shielding to prevent oxidation and enhance weld strength.

Q4: Is the machine easy to operate?

A4: Yes, it features a touch screen and CCD alignment system. Beginners can learn to use it within one day.

Q5: What are the advantages over traditional mold cold welders?

A5: It offers stronger, more precise welds, with smaller heat zones and faster processing—reducing the need for rework.

111-1024x458.png)