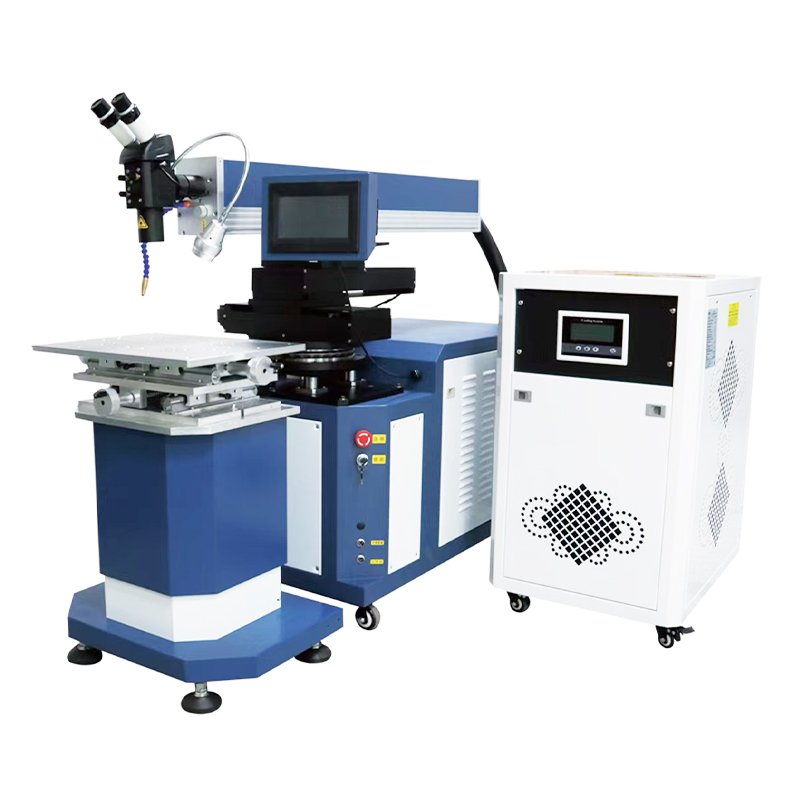

YAG Mold Laser Welding Machine

High-precision YAG mold laser welder designed for accurate repair of high-reflective and thin-walled molds. Features small spot size, minimal deformation, and strong weld strength, ideal for the mold industry’s demanding repair tasks.

This is popup title

You don't need to waste your time and money anymore.

Description

Laser YAG Mold Laser Welding Machine Product Introduction

The YAG mold laser welding machine is a high-precision welding solution specially developed for the mold industry. It uses high-energy density pulsed laser to perform precise welding and repair on tiny areas of molds. Its core strengths include low heat input, small weld spots, and controllable welding depth. It is particularly effective for micro-cracks, edge chipping, blade reinforcement, and pit filling. Even with highly reflective materials like copper and aluminum or hard alloys like titanium alloy and tungsten carbide, this machine delivers excellent results, achieving post-weld hardness of HRC50+ without pores or cracks.

YAG Mold Laser Welding Machine Core Advantages

Ultra-fine welding spots ideal for microscopic repair areas

Extremely low heat input, heat-affected zone < 0.1mm with minimal thermal deformation

Excellent performance on copper, aluminum, and hard alloys with over 98% yield

Adjustable laser energy, frequency, and pulse width for precise control

Post-repair hardness up to HRC50+ with no pores or cracks

YAG Mold Laser Welding Machine Application Scenarios

1.During plastic injection molding, long-term exposure to high pressure and temperature can cause micro-cracks that affect product quality. YAG laser welding enables distortion-free micro-crack repair, ideal for mold cores and cavities.

2.Die-casting molds for aluminum or zinc alloys often suffer edge wear or chipping due to thermal erosion. YAG laser welding offers low-heat, precision repair to restore mold integrity and extend service life.

3.In multi-cavity molds, localized damage can be costly if full replacement is needed. YAG laser welding allows precise local repairs without disassembly, greatly reducing maintenance costs.

YAG Mold Laser Welding Machine Demo

This video showcases the JOYLASER YAG Mold Laser Welding Machine performing precise repairs on mold surfaces. Utilizing YAG laser technology, it provides high peak pulse energy, ideal for welding micro-cracks, pinholes, and worn edges on mold steels such as P20, H13, 718, and SKD11.

The machine offers low heat input to minimize thermal distortion, ensuring smooth, clean welds without cracks or discoloration. Its precise control and stable output make it suitable for injection molding, die-casting, and stamping mold maintenance. The YAG laser’s pulse characteristics allow fine control over welding depth and width, delivering high-quality results on complex mold geometries.

YAG Mold Laser Welding Machine Technical Parameters

| Parameter | Value |

|---|---|

| Laser Type | Pulsed YAG |

| Wavelength | 1064 nm |

| Max Laser Power | 200W / 300W / 400W (optional) |

| Pulse Frequency | 1–50 Hz (adjustable) |

| Pulse Width | 0.1–20 ms |

| Focal Spot Diameter | 0.2–2.0 mm (adjustable) |

| Cooling Method | Water Cooling |

| Operation Mode | Microscope Observation + Manual Arm |

| Power Supply | AC 220V ±10% / 50Hz |

YAG Mold Laser Welding Machine Customer Cases

1.A plastic mold factory in Mexico suffered from recurring micro-cracks in the mold cavity, causing defects in molded parts. With the JOYLASER YAG Mold Laser Welding Machine, they achieved precise repairs without dismantling molds. The smooth and fine welds simplified polishing. The customer reported a 30% increase in mold lifespan and significantly reduced defect rates, improving product delivery quality.

2.A Turkish auto parts supplier using aluminum die-casting molds faced frequent edge damage from thermal erosion. With the YAG laser welding machine, they performed accurate repairs even on complex mold surfaces, achieving strong metallurgical bonds. The client noted a sharp reduction in rework and significantly improved production stability.

3.A Korean medical mold manufacturer needed micron-level repairs on intricate mold cavities. Traditional welding caused thermal distortion. The YAG laser welding machine delivered low-heat, high-precision results, enabling quick repairs without compromising mold accuracy. The client significantly improved mold turnover and production continuity.

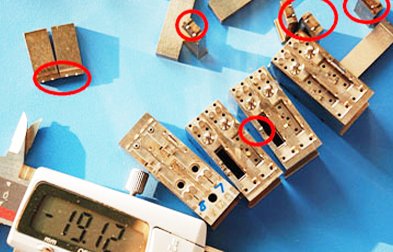

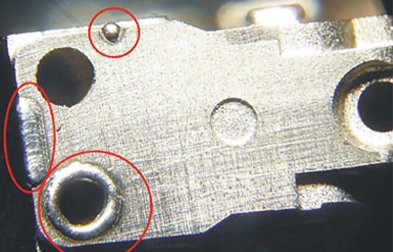

YAG Mold Laser Welding Machine Welding Example

YAG Mold Laser Welding Machine FAQ

Q1: What types of molds can the YAG mold laser welding machine weld?

A1: It is suitable for various types of molds, including injection molds, die-casting molds, stamping molds, optical molds, and copper electrodes.

Q2: Can the hardness of the repaired area meet production requirements?

A2: Yes, the repaired area can reach a hardness of over HRC50, which is sufficient to withstand normal mold processing strength.

Q3: Is it suitable for repairing high-reflective materials such as copper or aluminum?

A3: Yes, the YAG laser mold welding machine performs excellently on high-reflective materials, achieving a success rate of over 98%.

Q4: Is the operation complex? Does it require professional personnel?

A4: The interface is user-friendly and works with a microscope and manual arm. After proper training, regular technicians can operate it efficiently.

Q5: Will the welding process cause mold deformation?

A5: No. The machine adopts a low heat input welding method, with a heat-affected zone smaller than 0.1mm, resulting in minimal deformation.

111-1024x458.png)