Why Are More Manufacturers Choosing Laser Welding for Battery Tabs? A Full Advantage Breakdown

Introduction

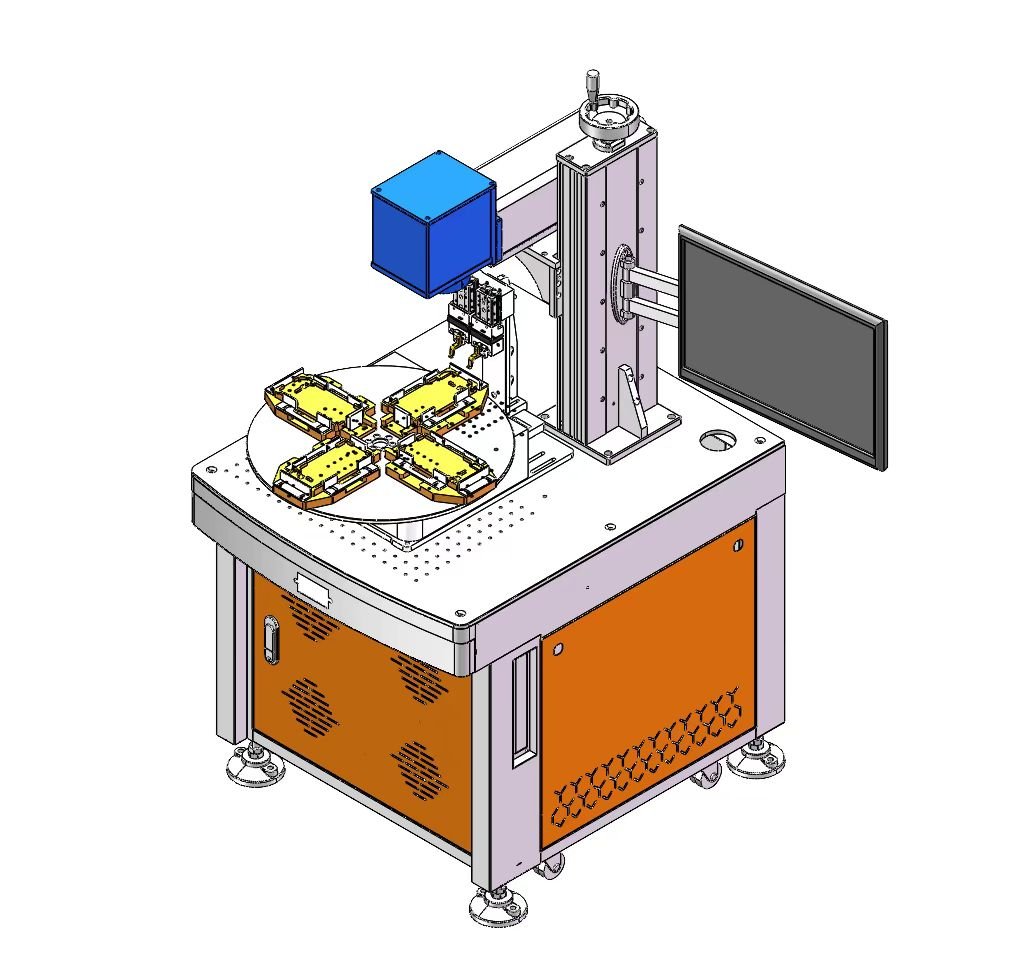

For battery manufacturers, the welding quality of battery tabs directly determines the safety and performance of the final battery product. Traditional welding methods such as resistance welding and ultrasonic welding often suffer from unstable weld seams, tab heat deformation, and low production efficiency, becoming bottlenecks that restrict battery production line upgrades. Our battery tab laser welding machine, with its ultra-high precision and intelligent operation design, perfectly overcomes these industry challenges.

Compared to traditional welding methods, our battery tab laser welding machine offers three major core advantages that stand out prominently:

1.Micron-Level Welding Precision

The laser spot diameter can be precisely controlled within the range of 0.1–0.3 mm, enabling accurate welding at the connection between the battery tab and the pole without damaging the surrounding electrode sheets or separators. This equipment is compatible with copper, aluminum, and nickel-plated copper tabs with thicknesses of 0.05–0.3 mm. The resulting welds are smooth and dense, free of pores and cold welds, effectively eliminating the risk of battery short circuits caused by welding defects. We provided a customized solution for a new energy battery manufacturer whose welding defect rate dropped from 1.2% to 0.03% after using our machine, earning high praise from the client.

2.High-Efficiency Continuous Operation

The machine is equipped with an automatic feeding and positioning system, with a welding cycle of only 0.8 seconds per weld, enabling 24-hour uninterrupted operation. It can seamlessly integrate with existing battery assembly lines, increasing production efficiency by 40% compared to manual welding. Additionally, the laser welding process has low heat input, minimizing tab heat deformation and ensuring consistent battery performance.

3.Intelligent and Convenient Operation

The machine features a human-machine interface touchscreen that allows presetting welding power, speed, and spot size according to different tab materials and thicknesses. Even operators without professional welding experience can quickly master it after just one hour of training. Additionally, the device is equipped with a real-time welding quality monitoring system that automatically alarms and stops the machine if any welding abnormalities are detected, preventing defective products from entering subsequent processes.

The reason our laser welding machines have earned the trust of battery manufacturers worldwide lies in our strict quality control system and reliable after-sales service. Core components such as lasers, galvanometers, and control systems use well-known brands. Each machine undergoes 72 hours of continuous operation testing before shipment to ensure quality. We also provide 12 months of free after-sales service and lifetime technical support, covering remote guidance for installation, debugging, and operator training. (Service centers are established in India and the USA for on-site technical support, with additional locations expanding globally.)

Frequently Asked Questions

Question 1: Can this machine be adapted for different types of battery tabs?

Answer 1: Yes. Our machine can adjust welding parameters for copper, aluminum, and nickel-plated copper tabs of various materials. It is also suitable for cylindrical, prismatic, and pouch-type batteries.

Question 2: What is the maintenance cycle for the equipment?

Answer 2: Under normal use, the core components require no maintenance within 2 years. Routine maintenance is simple, requiring only weekly cleaning of the lens.

Question 3: Is the laser welding process environmentally friendly?

Answer 3: Absolutely. The laser welding process produces no harmful gases or slag and consumes only 30% of the energy used by traditional welding equipment, fully complying with global environmental standards.

Whether you are a small-to-medium battery manufacturer seeking to upgrade your production line or a large new energy enterprise aiming for high efficiency and quality, this battery tab laser welding machine will be a reliable partner for your production. Contact us now to get free welding test videos and a customized quote!

111-1024x458.png)